(Part 2) Best welding & soldering according to redditors

We found 4,015 Reddit comments discussing the best welding & soldering. We ranked the 1,086 resulting products by number of redditors who mentioned them. Here are the products ranked 21-40. You can also go back to the previous section.

What a beautiful shot! Sometimes sacrifices must be made haha.

If you dont mind me making a small suggestion, I would try using an abrasion resistant polycarbonate infront of your lens because its the least likely to scratch or pit from debris. You can get just basic polycarb for like $5 so you could also just buy 10 and use them as disposable parts. It would save you a lot of money in the long run, and polycarb is the least likely to warp your image and if you get the thin stuff (under 0.5") it will have minimal effect on your light.

As for dew, you really just need to make sure youre above the dew point. If you have a power source, I would just buy a heat gun and point it at the edge of the poly carbonate, about a foot away. This way air is traveling along the surface of the polycarb and the lens. This would whisk away anything on them, heat them above the dew point preventing any of it, and wouldnt blow any dust in the way.

Anyway, great to read these detailed accounts from first hand photographers. Than you so much for sharing!

Its a solder sucker, used to de-solder components. You press the plunger down, then heat the solder then press the button on the sucker with the nozzle next to the solder and gone. Here is a link

Well you could save yourself $2900 and just house one of these in a nerf gun rifle with a custom paint job...

https://www.amazon.com/dp/B00282LP34/ref=sxbs_sxwds-stvp_2?pf_rd_m=ATVPDKIKX0DER&pf_rd_p=3341940462&pd_rd_wg=OpZHd&pf_rd_r=WWRMWNH8J98VB371Y7NR&pf_rd_s=desktop-sx-bottom-slot&pf_rd_t=301&pd_rd_i=B00282LP34&pd_rd_w=oO6q7&pf_rd_i=Propane+torch&pd_rd_r=bf89caa9-5455-445f-9334-3f3e141728f1&ie=UTF8&qid=1518034992&sr=2

Propane Torch.

https://www.amazon.com/Hot-Max-500G-Propane-Torch/dp/B00282LP34/ref=sr_1_1?ie=UTF8&qid=1537380675&sr=8-1&keywords=driveway+cleaning+propane

I've started to get into electronics myself, and I can say that soldering is easy, but you need the right tools for the job.

You'll need an adjustable temperature soldering iron and 1/2 milimeter iron/lead solder as the bare minimum.

I suggest grabbing some tip tinner, solder wick & vacuum, and some cheap boards to practice soldering.

This video shows how to do the actual soldering, while this video covers the tools you'll need and explains their use. These videos are made by EEV Blog and explain soldering in GREAT detail, which is how I learned to do it.

As far as making actual circuits, you have to have an idea AND parts to fulfill your idea. The Arduino UNO is a great way to program and test circuits. It's essentially a small comptuer designed to repeat whatver task you give it over and over. Alternatively, there's the Raspberry Pi, which comes in a few different models. The difference between the Pi and the Arduino is that the Pi is essentially a mini computer. You can literally hook it up to a monitor via hdmi and slam an operating system into it.

Both boards typically come in kits like this one for the Ardunio, or this one for the Raspberry Pi. The Ardunio kits with come with a lot of peripherals, like sensors and LEDs that actually do things, while you'll have to invest more with a Raspberry Pi. These kits come with detailed instructions, code you can copy and paste, and are a great way to learn how circuitry works, and is exactly what I'm doing right now. I'm no expert by any stretch of the imagination, I've just done a decent amount of research to find out what's what.

There are two ways to hook up circuits - temporarily and (somewhat) permanently. Breadboards are used to prototype circuits without having to solder anything, typically using these wires to link different parts of the circuits together. Soldering components to those green boards I linked earlier is what you'd do when you have your circuit up and running and want to move it to something more permanent. I say "more" permanent because you can usually de-solder stuff if you needed a component for something.

Adafruit has a decently sized library of projects you can try. They often sell stuff in kits where you get everything you need to make something -- for example, this DIY MIDI controller.

Sparkfun has a great series of articles that explain the very basics of circuits and electricity

Hopefully I've explained everything enough so that you can venture off on your own. Feel free to ask questions!

Holy mother of god..

I'm assuming it's any or a combination of:

Those definitely look ruined. :/

Having the right tools is super important for soldering/desoldering, especially if you lack the experience/know-how. If you used a desoldering braid/solder wick, one with better quality will make a massive difference when you're trying to desolder. I remember struggling with a cheap wick/solder sucker combo I got a while back. Switched to a Chemtronics Desoldering Braid and was shocked at how much easier desoldering could be.

Oh man, something I can finally contribute to on this sub, I do electronics repair and a ton of microsoldering. Sorry to hijack but I'm here way too late and a main level comment will never be seen

Solder naturally wants to stick to copper (the circular "pads" are copper or some copper alloy, and the legs should have some amount of copper in it as well) when it's liquid, so getting a 'volcano' is a lot easier than you'd think. The trick is to keep the pad, pin, and solder you're feeding in hot, as soon as it starts to solidify it becomes significantly more work to re-heat and rework. If it's not perfect, I wouldn't worry about it. As long as it's making solid contact and wouldn't come loose from you tapping the key, you're good to go. Excess solder is perfectly fine as long as it's not bridging.

Another thing on solder, GET LEAD SOLDER, lead free solder is a giant pain in the ass. It doesn't melt easily, clumps and balls up, and will not heat up evenly. Also have proper ventilation, solder/flux fumes are not good.

Another possible reason for having problems is your soldering iron tip being dirty/oxidized. If it's looking black or really dull you need to clean it in a wire sponge like this. Stick the tip in and furiously move it around. If it's still dull after that/you've used the same tip for a long time, you need to tin it with a tinner, like this (lead free is totally fine for this, just dip it in while it's hot for 1-3s and clean it in the wire sponge immediately after. Smoke is normal (don't breathe it in) and it'll come out real freaking shiny.

Flux is basically a liquid-gel-ish substance that covers whatever you're working on so it doesn't oxidize and make a bad connection, although for larger scale soldering like keyboards with a ton of contact area it's not nearly as much a concern. Flux also helps a lot with more even heat distribution, as in if you need to rework/remove solder just apply a ton of flux and it'll help heat up the solder more evenly/liquefy it more quickly.

Flux is non-conductive so you don't have to worry about it bridging anything, and you can leave it on if you want to but it's always good to clean it with 99% alcohol after because it gets dry and nasty pretty quick (about the same texture and consistency as dried jizz, pretty undesirable).

Wick is a copper weave that soaks up solder when you're trying to remove it. If you, for example, bridge a connection, you would apply flux over the whole area, put the wick directly over the spot, and your iron directly on top of that. You'll be able to see the solder flow 'upwards' through the weave and the copper will turn silver.

The finer the "weave" of the wick the more effective it is, finer also means more flexible so you can tell really easily. Once a section is silvery with solder you should cut it off and unroll some fresh wick. Also copper conducts heat really well so hold it far away from the place where your iron is touching it or use heat proof gloves if you want to (not rubber/latex ones, they'll probably melt into your skin or something).

P.S. If you're having a lot of trouble removing the factory solder, that's probably because it's lead free solder. Add some leaded solder and melt it in, everything will come out easier. If you're REALLY having issues after a ton of flux, use a heat gun, be careful to not melt the plastics on the other side, although the PCB usually isolates heat pretty well

P.P.S. Don't ever heat anything for too long, if it's not coming off check the temp on your iron (you can just see how melty it is, don't need a thermometer or anything), and if it's at a good temp try adding flux or solder or both, or get a better wick. If a pad comes off the board you're fucked unless you wanna spend an hour jumping.

P.P.P.S. If you have the option, go for a blade-style soldering tip. It's really good for rougher applications like this and heats things up super fast.

ama if anyone still cares

> Knowing next to nothing about assembling something like this, could a complete newbie make one?

Providing you can follow instructions it would be like constructing a more advanced Lego set.

If /u/progidek shares his EAGLE design you can print it onto some double sided copper PCB using a DIY etchant kit and an inkjet printer or finding something similar.

Parts should just be a matter of searching part numbers into Jaycar, Amazon, Sparkfun, Element13 or other similar sites.

Assembly can be done by following pictures, just make sure polarity is correct. Usually one side is different to show the polarity; silver ribbon on 1 side, longer leg, deformed side. This will be the most time consuming step, but mistakes can be undone using solder wick.

Soldering is easy to do, but not so easy to keep as clean as /u/progidek did, it's really quite gorgeous. There are a few youtube tutorials on how to's and improving technique.

You may want to start on a pre-packaged kit to build up some skill

You may have heard the old saying:

>The road to success is through experience.

>

>The road to experience is through failure.

It sounds like you have already achieved some failure, so this means you are well on your way on the road to success!

Let me add another old saying that I just made up:

>Good technique may overcome a bad soldering iron.

>

>A great soldering iron will never overcome bad technique.

You didn't mention what kind of iron and what kind of solder you are using now. But if you are getting cold joints, that is more likely a sign of bad technique rather than the wrong iron.

Cold joints happen when you heat the solder instead of heating the work material. The hot solder hits the cold metal and freezes in place instead of flowing onto the hot metal.

You need to heat the work material itself first. If it's a through-hole component, then after you turn the board upside down, touch the iron to both the component's wire lead and the board's pad. Only after both of those heat up do you apply the rosin core solder to melt onto and into them. Then you will have a beautiful shiny solder joint.

This does take some finesse and attention to timing. So I would do this Heathkit style. The Heathkits I bought when I was a teenager always came with clear instructions on how to solder, and most importantly, some extra pieces to practice with. I learned to get the technique down on those before tackling the kit itself. So practice on scrap material until you have it down.

Of course a good iron and good solder will help. If you're using lead-free solder, I might suggest a traditional lead-tin solder instead, as it is easier to work with.

For an iron, you didn't mention what you're using now, or what your budget might be. If something around $100 works for you, you can't go wrong with the Hakko FX888D. You might want some extra tips of various sizes too.

Desoldering is an art to itself. Do you have some desoldering braid? I used to use the "soldapullit" suction pumps and similar things, but the braid always gave me better results. It comes in different widths so you can pick one that fits the work you're doing.

I hope these notes are helpful. Holler back with any questions, and happy soldering!

A couple of things come to mind:

A) Cool.

B) Instead of drilling through your stencils, I recommend using a finishing nail or an awl and banging pilot divots. This centers and guides the drill bit, and keeps you from killing your stencil, just in case.

3) Try heat shrink tubing. It's not terribly expensive, it's fun to use, and it makes you look clever.

D) In the event that you ever want people to think that you are very clever, get a decent soldering iron. If you have a lot of extra money to throw around, get a fancy Weller station. If not, I recommend the adorable Hakko FX-888. Now that the analog version has been discontinued, it's hard to find on sale, but... they're fantastic. If you want to feel fancy, you could get something like this. Look at all those bits! I don't know either!

Screw that. If you really want to have fun use one of these. Burn it up.

Tell Best Buy to go suck a lemon.

Good basic guide. I would add that most people get flux cored solder, so they don't need to work about fluxing before solder.

Second thing is, if you're going to do more than one keyboard's worth of soldering, I'd suggest ditching the sponge and getting a brass / copper wire tip cleaner.. It's not super great for the tip to be put on a wet sponge.

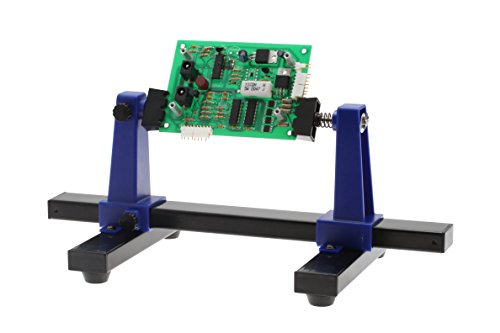

Aven 17010 Adjustable Circuit Board Holder https://www.amazon.com/dp/B00Q2TTQEE/ref=cm_sw_r_cp_apa_mFZ-BbDJWGWJ4

Preface: for some ungodly reason Mass Drop expects people to create an account before showing what the page has.

What is on the page is the description of the keyboard along with everything in the kit.

Here is an image of the web page to fix this so that you can see what keyboard I am talking about: https://minus.com/lE02abi6ORu87.png

It is stupid I know, but that is how they are for some reason.

You don't have to use Facebook to log into it though thankfully.

Alright, so this kit is finally back as an option on Mass Drop after over a month or two of absence, and it is on it's third or fourth Mass Drop group buy, all of which have been successful with no complaints from buyers amazingly.

Ordering it as a group buy is the only way to get this keyboard and it isn't offered anywhere else on the planet.

Everyone who has tried the keyboard is in love with their ErgoDox and how comfortable using the brilliant design is.

The ErgoDox keyboard is an open source hardware, open source software design, which as people who use GPLv3 software I hope you can appreciate how huge that is in light of how unapproachable hardware design has been in the past, plus with the group buy concept instead of the total cost being over 1500 USD (I priced all of this thinking to make my own being very unhappy with the lack of any intelligence present among keyboard manufacturers) it is less than 300 dollars, even after purchasing keycaps, which is huge.

What is brilliant about this keyboard, and I mean absolute genius in a domain defined by the lack there of is that it uses open source hardware with the specifications fully available, open source software for the firmware, the micro controller is very easily modified and installed thanks to their work on the configuration software, it uses all high quality parts including the very popular Cherry MX key switches (the mechanical part of a mechanical keyboard) for excellent tactile feedback and soothing ambient noise through the clickity clackety of the key switches, provides everything you need in the kit, has excellent instructions for assembling them, and allows you to decide on your own term caps, for which there is another group buy for to bring the cost of those way down.

You will absolutely love having thumb keys, which I use for all of my modifier keys and it saves my hands from career ending emacs pinky thankfully. Thumb accessible keys is an absolute boon for the information worker that has long days and nights.

I have liked them ever since experiencing them on a Kinesis Contour Advantage keyboard, and I cannot recommend that design enough.

But wait, there's more: in addition to all of that the keyboard also brilliantly went with not only a mirrored, symmetric layout for the keys and frame, and it also had the insight and genius to go with a split-keyboard layout so that the keyboard can not only accommodate a variety of human sizes, but doing so also ensures that the user can conform to proper ergonomic keyboard uses that entails having the arms and hands orthogonal to the key layout.

And even then, this design has another stroke of genius: removal of the typical function keys and escape key.

I know, you are thinking this is insane I need those.

And yes dear reader, I thought so too, but here is why this is actually a good thing, by not having that row there not only does it save space, it also ensures that you do not have the courage to try and chord the function keys without leaving the home row and anger the tendon gods in the process.

Thanks to the multiple layouts available (more not that below) you don't actually lose access to these, they just move to wherever you have decided to locate them.

This design is the most comfortable and ergonomic keyboard design I have ever seen and it puts the rest f the industry to shame for their hubris that has ruined many a career and been generally bereft of excellence as it makes no sense to design a keyboard this way now that we are not using bloody type writers from middle ages.

I am going to order at least two myself, one to use then a backup in case I can't get it in the future, which is what has happened to another keyboard design I liked and made it impossible to get or very expensive. Also, so I can take one to work and leave another at home.

Anyways, for those of you who do not have electronics experience and are worried about soldering things together or flashing the firmware on the micro-controller, do not be alarmed.

It is quite easy if you have moderately steady hands, plus you will learn a cool skill and hopefully take up the joy of hobby electronics.

You will be able to make your own ham radios and mess around with the great arduino micro-controllers and do all kinds of awesome tricks with sensors in your residence or wherever.

I recommend getting a fine point soldering iron and desoldering pump sucker for picking up solder off the pcb if you need to redo a trace. A soldering iron like this will work fine for this project.

A beautiful person took the time to make a how to assembly video showing the entire process too, which is superb: https://www.youtube.com/watch?v=x1irVrAl3Ts

This image has the assembly instructions that cover the soldering and other hook ups: https://i1.minus.com/ibeVgc381INcEF.jpg

Here is the configuration page you use to set up the layout and the site generates the hex file you need to upload to the firmware for you, which is the tricky part normally: https://www.massdrop.com/ext

Here's an image mirror of that in case the previous link does not work: https://i.minus.com/ivk3kHgNCgsTl.png

Here is an example modified qwerty layout. https://minus.com/l5Tnw5yL3TuMb.png

There are multiple layers because on this keyboard you can have multiple layouts that you jump up and down through via the L+ and L- keys, which is absolutely brilliant design.

L+ moves up in the layout stack, and L- moves down in the layout stack.

Also, you can configure keys to move up or down through two layers at a time for ever faster switching between layouts.

Having a way to progress through multiple layers of layouts is something I had not thought of in my prototype design and would have sorely missed having such a wonderful feature if I had not seen the ErgoDox keyboard before I had a go at having my own custom layout manufactured.

I really cannot hype this design enough, from quality to its concept to its execution, every aspect is flawless and free as in freedom on top of that.

I hope you all consider grabbing this beautiful product.

I realize it is considerably pricy compared to other keyboards, although within a normal price for ergonomic keyboards, but this is absolutely an investment in your own health and career regardless of your age that will pay for itself.

It is a pittance to pay for compared to the agony that will succeed if you happen to come down with crippling repetitive stress injury (RSI) or carpal tunnel syndrome (CTS).

As someone who has had that, and also as someone who did not take the situation seriously, it is completely devastating and takes months to heal even with great precaution and doing everything possible outside of surgery (which at most will have 80% return of functionality in your hands and ensure that you will be maimed for life in the process).

It is much, much better to go with the ounce of prevention instead of the pound (and months to years) of cure along with hundreds of dollars in the process that entails an slew of treatments.

Even one lost paycheck due to injury will cover the cost of this investment in yourself.

If you choose not to go with this product, at least take the time to invest into researching how to avoid injury and what you can do to give yourself the best chance of staying in the game rather than being sidelined by injury and wasting your own time and brilliance.

Xah has reviews of other keyboards (none of the ErgoDox that I know of though) that are ergonomic options as well. You can find those reviews here: Xah's reviews.

I'll just give you a list of the items I've been using (and like):

https://www.amazon.com/Hakko-T18-D08-D12-D24-D32/dp/B00C1N30DI Hakko FX-888D. The extra tips may be unnecessary, I only ever use the one chisel tip

https://www.amazon.com/gp/product/B00068IJPO Leaded solder

https://www.amazon.com/gp/product/B004SPGFT8 Brushes

https://www.amazon.com/gp/product/B00FZPDG1K Side cutters

https://www.amazon.com/gp/product/B00425FUW2 Flux

https://www.amazon.com/gp/product/B008O9VLA2 Solder Wick

https://www.amazon.com/gp/product/B0013HT2QW KimWipes

https://www.amazon.com/gp/product/B001B5JT8C Isopropyl Alcohol

https://www.amazon.com/gp/product/B005CU56KM Acetone spray (use carefully/sparingly)

https://www.amazon.com/gp/product/B004G5T9M0 Jewelers loupe

https://www.amazon.com/gp/product/B019SLLOMY Tweezers

https://www.amazon.com/gp/product/B00P8Z4RPG Hot air station (works well despite Chinesium)

Also, I noticed in Dave's videos he rarely adds flux, just the flux that's built into the multicore solder. I don't know if I'm alone on this one but with flux I always felt the bigger the glob the better the job. Just have to clean it afterwards with the solvent, tissues & brushes.

Edit: Okay that's a much bigger list than I thought, this stuff can get expensive!

I have this one and it's served me well for the last few years. There's also an analog version. The digital ones only read in Celsius, if that bothers you. They definitely aren't as nice as a Hakko or a Weller, but it has never let me down.

As far as the fumes go, it isn't the lead that's the problem, it's the flux inside the solder. Lead doesn't vaporize until ~1700C, which your iron is never going to reach. I mention this so you know that lead free solder doesn't solve the problem.

You should either solder in a well ventilated area, or use a fume extractor. Commercial fume extractors are expensive, and you can make your own with fan and a carbon filter (you can get them for normal air filters and cut to size).

I did a BYOC kit over a year ago.

It can be difficult if you don't have the right tools. I got a board holder that made my life so much easier.

I also suggest getting a very fine/narrow solder tip. The one I used was a little big for the job.

The most difficult part was soldering the switch. Pisses me off just looking at it.

In the end the pedal had a huge volume drop, so I fucked something up along the way.

Soldering iron: Hakko FX888D Digital Station with a 5 ft. Spool Soder-Wick Desoldering Braid https://www.amazon.com/dp/B015YGBUO4?ref=yo_pop_ma_swf

Solder: Kester 44 Rosin Core Solder 63/37 .031" 1oz Dispense-Pak https://www.amazon.com/dp/B00AVLM4SO?ref=yo_pop_ma_swf

Get yourself a Weller WE-51 http://www.amazon.com/Weller-WES51-Analog-Soldering-Station/dp/B000BRC2XU

and some Kester 63/37 solder http://www.amazon.com/Kester-Rosin-Core-Solder-Dispense-Pak/dp/B00AVLM4SO/ref=sr_1_3?s=hi&ie=UTF8&qid=1454222158&sr=1-3&keywords=kester+63+37

That's all you need

I bought this a while ago, which has been fantastic for filling boards and soldering components. It gets tough if you have components really close to the edges, but that's why I also use a regular old helping hand tool.

This. You can find decent starting irons on Amazon with solder. You might consider buying a few ”learn to solder" soldering kits from Amazon. They come with all the parts needed, and the instructions teach you how to assemble the components (you then have to solder them in the board it came with)

Iron set example: (good for basic /beginner projects) https://www.amazon.com/gp/aw/d/B01H1IFT54/ref=mp_s_a_1_4?ie=UTF8&qid=1523313329&sr=8-4&pi=AC_SX236_SY340_FMwebp_QL65&keywords=soldering+kit&dpPl=1&dpID=51rAt23O28L&ref=plSrch

Electronics kit beginner example (these are fun to do imo)

https://www.amazon.com/gp/aw/d/B0002LUAL6/ref=mp_s_a_1_2?ie=UTF8&qid=1523313465&sr=8-2&pi=AC_SX236_SY340_QL65&keywords=elenco+soldering+kit&dpPl=1&dpID=519bj4ev-jL&ref=plSrch

Although not the cheapest, ebay is probably the easiest way to find faulty systems.

Some equipment recommendations:

Probably depends on the quality of the wood burner. In most cases they are basically just soldering irons with different tips. You can get variable temperature soldering irons for $12. http://www.amazon.com/Stahl-Tools-Variable-Temperature-Soldering/dp/B0029N70WM

As stated, 99% chance it's blown caps (capacitors). It's a very common problem with today's cheaply made TVs and computers.

The good news is that they are actually pretty easy to diagnose and replace. There are tons of video tutorials that will walk you through it. It only takes about 20 minutes maybe to do the whole thing for about $35 - $40 bucks. Then if it ever happens again with another TV, it's only about $15 each time after. So, instead of throwing out that TV, you can repair it for $40; so not bad!

First, you want to diagnose if this is the problem. Lay your TV down on a flat surface and take off the back, usually just need a screwdriver. Look at the capacitors (which look like very short AA batteries) and if they are blown, the tops will be leaking, bulging, and/or oozing. There are TONS of Google images to compare against.

If it is the caps, all you need are 2 things:

The videos will walk you through how to do it, including use the soldering iron. It's pretty easy. For what it's worth, I am a woman, with no electronic background and have now replaced and fixed 3 TVs that I've had this happen to.

I hope this helps!

I use the cheapest solder wick I could find on Amazon (like $1.50). The trick is to soak it in flux (which I also got off Amazon).

Edit: The wick I use and the flux.

I do a back yard show too and I find the board method too cumbersome. I now use the duct tape/bag/stake method.

Not a fan of roman candles. Dont waste your money.

Make sure you test your fuse and know what speed it burns. My white fuse burns super fast. My green fuse burns faster than my yellow. My yellow burns much faster than the Pink. The pink is slower than the Shiny green fuse. That wasn't always the case. My green fuse was always the slowest and yellow was the fastest.

I also don't like the idea of reloading shells during the show. If you must, you can prep them by zip tying the fuses together in groups of 8 or so. Throw 8 in the tubes and light the bunch. Dont put your head over any part. Stick the rest of prepped shells in a ready box. A ready box is designed so it cannot be left open. You lift up the lid, grab a bunch, the box has a string so that closes itself after opening

Invest in zip ties and metal tape. Use this to tie your fuse together.

https://www.amazon.com/3M-Foil-Tape-3381-Silver/dp/B00A7I5L86

https://www.amazon.com/Aviditi-CT422E-Nylon-Length-Purple/dp/B00DY98M1I/ref=sr_1_3?s=office-products&ie=UTF8&qid=1525752899&sr=1-3&keywords=4%22+zip+ties

I cant begin to tell you how much I love these fuse cutters. This tool changed my fuse cutting life. I spit on scissors now.

https://www.amazon.com/Craftsman-Edge-Utility-Cutter-9-37309/dp/B0037IX2BG/ref=sr_1_12?s=power-hand-tools&ie=UTF8&qid=1525752808&sr=1-12&keywords=handi+cut

This fuse igniter will change your life. Lighters might as well be flint. Thats how next gen this is. Get some propane or MAPP

https://www.amazon.com/Bernzomatic-TS4000-Trigger-Start-Torch/dp/B00008ZA09/ref=sr_1_3?s=office-products&ie=UTF8&qid=1525753004&sr=8-3&keywords=berzomatic

This headlamp makes flashlights a thing of the past and changes your life. Make sure you get one that doesnt have a third strap along the top. If youre not using it you can wear your headlamp on your neck and not lose it.

https://www.amazon.com/Black-Diamond-Spot-Headlamp-Octane/dp/B06W9HPY25/ref=sr_1_6_twc-13d22461-ce_1?ie=UTF8&qid=1525753147&sr=8-6-acs&keywords=head+lamp&content_id=13d22461-ceea-426c-b620-9fe11db17513&ascsubtag=13d22461-ceea-426c-b620-9fe11db17513&tag=ospsearch-20&widget_name=expert_recommendation&content_provider=osp&ingress=search&content_type=story

Also invest some money in some eye and ear protection. I can't tell you how many times I went to bed with a "reeee sound" in my ears, and have gotten pyro shit in my eyes.

Build yourself some real racks if you're up for it. I just recently built myself some and it was a snap.

https://www.youtube.com/watch?v=-p7J4HV4Gak

If you're taking your first steps into wiring, then you should get comfortable working with wires and tools. Here is a kit that will introduce you to wiring, soldering, etc.

Along with that, there are a few tools that might be useful to you:

And there are videos on YouTube that will teach you how to properly solder a wire to a soldering point. For that Elenco kit, the main goal is to get both the siren and the flashing lights to work, which it will if you wired everything correctly and used the correct resistors. It can be easy to make mistakes while learning to solder for the first time but most mistakes can be fixed, and it's very difficult to cause enough damage to render the board completely unusable.

Also, one note of caution: soldering irons are extremely hot, as the intent is to liquify the solder and attach it to the soldering points.

Don't buy 60/40 solder. Buy 63/37.

https://www.amazon.com/dp/B00068IJOU/

https://en.wikibooks.org/wiki/Practical_Electronics/Soldering

So, what's the difference between this sort of solder that has the flux separate and the electronics type solder that I'm more familiar with used with a soldering iron?

This is highly recommended: Kester 44 Rosin Core Solder 63/37 .020 1 lb. Spool https://www.amazon.com/dp/B00068IJWC/ref=cm_sw_r_cp_api_Tn0vybNY3QZ01

And if you plan more than one project this soldering iron is great: Hakko FX888D-23BY Digital Soldering Station FX-888D FX-888 (blue & yellow) https://www.amazon.com/dp/B00ANZRT4M/ref=cm_sw_r_cp_api_Bo0vyb4YNQS1G

Build Log 5: Viterbi

Highlights

Parts List

Resources

Tools

Notes

pffft... flamethrower my ass; https://www.amazon.com/Hot-Max-500G-Propane-Torch/dp/B00282LP34

a ten dollar supersoaker and five bucks worth of gas is closer to a flamethrower than the 500 dollar trinket musk is selling here...

Unless they're going to make propane torches illegal that "flamethrower" is going to sell like hotcakes to every idiot with 500 dollars to burn...

Use a propane torch. Before herbicides it was standard.

You have to wet it down first, to 'boil' the roots.

propane torch

It's hard to tell because you used way too much solder, but it looks like you may have cold joints. Thick solder makes it easier to use too much, if your solder is wider than 1mm look into something narrower, I like 0.6mm. (60/40 rosin core preferably.) As for the joint, what you want to be doing is heating both pieces with your iron and then letting the solder melt onto the joint; that's a hot joint. If you just melt the solder onto the joint with your iron, that's a cold joint and you don't want it; they're much more brittle. You can put a dab of solder on the iron tip to help heat transfer (the faster you heat the pieces, the faster you can solder the joint and stop dumping heat into the components) but that solder is not for making the joint.

If you need to go back and fix those joints, invest in a solder sucker to remove it. (Or if you don't mind spending the six bucks, do it anyway, because that extra solder didn't help and can only hurt.)

There's a good series of EEVBlog videos on soldering if you want a more in-depth look at removing the "noob" part from "noob soldering job," Dave does a good job of explaining.

Lastly, if your iron looks like this, consider upgrading to a variable temperature iron like a TS100 (great for field repairs if you make an XT60 adapter for it) or this cheap Stahl, they're both worth the money. (The TS100 is the better of the two, and will work well enough for most small jobs to be your primary iron.) Those cheap pencil irons are pretty worthless, though they'll certainly work if that's all you've got.

soldering is your only real fix for that. You can get solder and an iron for under $10 on Amazon.

http://www.amazon.com/Aven-17542-Desoldering-2-5mm-Length/dp/B003E48ERU/ref=pd_sim_hi_7?ie=UTF8&refRID=188YPQ34V4XST3F9F6P4

http://www.amazon.com/Sinometer-Watts-Soldering-Iron-listed/dp/B0006NNRW4/ref=sr_1_5?ie=UTF8&qid=1419554378&sr=8-5&keywords=soldering+iron

Extreme overkill probably, but if you really want to spoil him...Best investment I have made tool-wise.

If he is just getting started I doubt he will need the hot-air rework side of things, but after a while soldering I wanted one for a long time before I actually got around to picking one up...

Mainly posting this here because I am a big Aoyue fan and everything here is Hakko and Weller.

For a soldering station I would consider new unless you find a great deal on something... For example, I use this at work, it's never given me a problem and it's used quite often (we're a semi conductor manufacturer and I share the lab with another)--granted we use a set of Wellers for most of the soldering, but the Aoyue gets high use for the heat gun and occasionally the soldering iron. I liked it so much that I bought one for home, yeah it's a bit high, but if you're doing SMD or other soldering stuff you will appreciate some of the features and included items.

I'm not sure about power supplies, but one good thing there is that age is usually not a big issue, and if you're just needing standard supplies you can probably get away with a decent 12V supply and then build a few regulators for lower voltages.

I've heard that Rigol oscilloscopes are a great value, and that that the lower rate units can be firmware hacked to higher rates. Personally the trouble I have is that after using $5000 Tektronics scopes at work I can hardly even stand to step down to a $2000 Tektronics, so I can't imagine what using a $350 Rigol would feel like... but if you have nothing, this isn't bad.

I'd also check out ham radio flea markets. BTW I have to say that if you are into electronics and what to make a life/career there is no better place to be than into amateur radio. the ARRL handbook alone is an amazing reference. As a personal responsible for documentation at my work I'm blown away by the quality of the writing for those handbooks. Even older copies are great and they're usually cheap. I have a 2003 copy at work and reference it regularly for either the information I need or a great starting place for researching a topic.

Genesis GHG1500A Dual Temperature Heat Gun Kit with Four Metal Nozzle Attachments https://www.amazon.com/dp/B00EU2T8GG/ref=cm_sw_r_cp_api_i_KJ6XCb0YS1FW2

This is the one I got, for less than $20. Great buy.

I've been using this: https://www.amazon.com/dp/B00Q2TTQEE/ref=cm_sw_r_other_awd_K3x8wb1ZQJWX1

It works great. You can easily flip your project over and see both sides of the board. I'm not sure how much smaller it is that the one you're looking at though.

SRA-Solder has items on Amazon, they sell Aoyue products in the US.

this would blow your whole budget, but would set you up so you could solder almost anything.

Got a soldering iron for Christmas and dove right in. This is my third 60% build, and by far my favorite.

Parts

Tools

I'm still tweaking my QMK keymap, but will contribute it to the repo once I get it to a good spot.

I'm still pretty new to this myself, but like you I have some electronics experience in the past. I just got this Weller 40w iron station with a desolder braid/sucker and a solder tip cleaner. Oh and a more precise tip for the solder iron

I'm really happy with it all so far, and couln't imagine needing more for a while. A heat gun would be nice for de-soldering and reflowing premade boards (like modding Boss pedals), but that can also be done with a regular solder iron as far as I know. You can get the above for about $60 total, so it's a nice way to get your feet wet without a huge investment. Then you gotta add on components/enclosures/pots/switches etc. Maybe get a helping hands and/or circuit holder if you need

Oh and get a good multimeter. I went a step up from the $20 ones and got this one which I'm also really happy with.

I highly recommend using one of these to remove components: https://www.amazon.com/OMorc-Desoldering-Solder-Sucker-Length/dp/B01I14V4X8/ref=sr_1_5?ie=UTF8&qid=1519764865&sr=8-5&keywords=solder+remover it will make the job much cleaner, I wish I had brought one of these years ago.

>I am worried about the soldering

Soldering is easy. Use this solder and a decent quality hot pen, optimally with adjustable heat that goes up to 500C, you'll need the extra heat for soldering down the 12ga power wires to the flat contacts on the hotbed. I bought this kit on a Christmas sale for like $20 and it was fantastic for my build; had everything I needed. The pen might not last a lifetime like a Hakko or Weller pro station, but it got the job done wonderfully and I'm sure it will get me through my second v3 build here in about a week. (yes, I love this one so much, I'm building a second!)

>cutting out of plastic pieces

There's no cutting anything out, everything is laser cut for you already, you just pop it out.

>is it pretty self-explanatory?

The instructions could be clearer, I'll say. They could definitely reorder a few steps to make the build a bit easier during later steps. That said, it all came together without any issues. Just make sure you keep everything WELL organized.

Now listen,

Disregard everyone on this sub that says "deltas are more difficult," including and especially those with "Rostock Max V2 w/E3dV6" in their flair! ;-) Seriously folks, the meme that deltas are more difficult is dead. Repetier firmare has advanced to the point where calibrating them is even easier than Cartesian and I mean that!

Just so you're aware, I had in my possession 2 Cartesians prior to building this delta, and the cartesians never printed 100 microns perfectly. Literally straight after I finished my v3 build, ran the calibration script, dialed in KISSlicer, and hit print, the Rostock was laying down 100 microns at 80-100mm/sec without issue. I've never had a print lift off the heated bed, and I don't use anything to increase adhesion, just the bare glass.

At .3mm layer height, I can push the speed to 160mm/sec which seems to be the limit of the 8-bit RAMBo board before it starts artifcating pretty routinely. Nothing severe, but there's definitely some imperfections at that speed. Guess what: no one on this sub is printing 160mm/sec on their Cartesians without it looking like absolute shit, and my 160mm/sec prints are passable for prototypes. You're just not going to get that much speed with that high of a precision out of a desktop Cartesian, even with a bowden. You just will not.

Much larger build volume. Lower maintenance. Awesome SeeMeCNC customer support. Higher precision. Faster build times.

Listen, I could have streched my budget and gotten 3 Prusa MK2s and had a friggen sweet little farm going for what I'm paying for two v3s, but the MAX v3 is simply the superior option if you can afford the slightly higher price over the MK2. If you can't hit $999+shipping, just get the MK2. If you can hit that target, just get the v3. It's a better printer.

These are all pretty solid Personally I'm a fan of Aoyue's products too, though both the units I've owned have been on the expensive side, I can link those if you're interested. For solder, I always use this stuff, it works great for switches and stuff like that and is small enough to work alright for SMD work.

Do not use that solder.

Do not use that solder iron.

I use 63/37 resin core solder mostly.

I use a Hakko FX888D (also get T18 compatible wedge tips).

Try this solder. I am using a thicker solder now, but I am going to switch to this one probably.

Some more advice: the wattage you use with cheap soldering irons like that depends on many factors. Do not focus on the temperature/wattage alone. What you want is to get the contact hot enough within 2 seconds to form a good joint. So, touch the iron, two seconds, touch solder, immediately wets and forms the joint (and you remove the solder and iron as the situation dictates).

solder connections are on the bottom of the board. It's going to be a bitch to get off without burning or peeling up leads - those boards are not meant to be re-worked. I'm pretty handy with soldering, this is not something I would attempt except as an absolute last resort, and if I did, I'd go into it prepared to have a ruined board.

If you want to have a crack at it:

But here are some better ideas:

Questions asked by chat during stream:

Question by /u/anthonyooiszewen:

------

Will edit comment if more come up, and of course corrections if I took notes incorrectly :D

Get yourself some desoldering braid, like this, or drop big bucks on a desoldering station. The braid is alright but can require a lot of patience and it needs a big, hot soldering iron.

FWIW, you're conflating soldering and welding. Welding fuses the parent metals and the filler metal together, whereas soldering simply bonds the filler metal around the parent metals.

Kind of off-topic, but if you end up needing a kitchen torch regularly, I'd suggest upgrading to something like this.

It'll run for what seems forever on a canister of propane camp fuel. Propane is a lot cheaper than butane as well.

Plus, it's a multitasker all around the house. I can go from finishing a sous vide steak to loosening the lug nuts on my car's tires. It has also replaced all the flaky lighters in my house.

I have this torch and use MAPP fuel. I would recommend:

Well, if you can use the lab and it has a scope in it then you just scored big time.

As far as $100. I would get:

(amazon links for convenience, use any supplier you wish)

EDIT: Light bulb socket, 100W + 60W real light bulbs (not the hippy engery saving kind), electrical outlet - these are for making a dim bulb tester.

All I can think of right now.

This is a pretty awesome iron

https://www.amazon.com/X-Tronic-Model-3020-XTS-ST-Soldering-Station-Complete/dp/B079VVHPPS/ref=mp_s_a_1_1_sspa?keywords=xtronic+soldering+station&qid=1572960802&sprefix=xtronic&sr=8-1-spons&psc=1&spLa=ZW5jcnlwdGVkUXVhbGlmaWVyPUE1SDY4UVpHMkNEOEomZW5jcnlwdGVkSWQ9QTAzNjMxNDRKQVlBOUE0WkRYMUcmZW5jcnlwdGVkQWRJZD1BMDYzMTgyNDFRNEdPRUZIV0g3NVgmd2lkZ2V0TmFtZT1zcF9waG9uZV9zZWFyY2hfYXRmJmFjdGlvbj1jbGlja1JlZGlyZWN0JmRvTm90TG9nQ2xpY2s9dHJ1ZQ==

And add the solder https://www.amazon.com/gp/aw/d/B00030AP48/ref=ppx_yo_mob_b_inactive_ship_o1_img?ie=UTF8&psc=1

Never burned solder with these two. Never over heated or melted anything that wasn’t supposed to be heated up.

Ec3 connectors

https://www.amazon.com/gp/aw/d/B00XC7QKF2?psc=1&ref=ppx_pop_mob_b_asin_title

You should be able to clean off the pads, re-tin them, and re-solder new wires to them.

You'll need a few tools:

Clean and tin the soldering iron tip:

Remove the solder from the pads on the heat bed:

Add some solder to the pads - you'll want a little bit of solder to cover the whole pad, with enough to make a small bump.

Tin the wires:

Attach the tinned wires to the tinned solder pads on the heat bed:

Also: You can use some isopropyl alcohol (rubbing alcohol) to clean up the excess rosin paste - it can get sticky.

Hope this helps!

The soldering iron you have is fine. I bought my batteries from console5.com . As far as other things, I would suggest some flux and a desolder braid/wick. If you don't have solder I would grab some of that too. I've got alphafry solder, mg chemicals desolder wick, and sra flux.

Batteries:

https://console5.com/store/panasonic-cr2032-3v-lithium-battery-with-solder-tabs-pins.html

Desolder wick:

https://www.amazon.com/gp/aw/d/B00424S2C8/ref=mp_s_a_1_6?ie=UTF8&qid=1525828012&sr=8-6&pi=AC_SX236_SY340_FMwebp_QL65&keywords=solder+wick

Flux:

https://www.amazon.com/gp/aw/d/B008OC0E5M/ref=mp_s_a_1_3?ie=UTF8&qid=1525828121&sr=8-3&pi=AC_SX236_SY340_FMwebp_QL65&keywords=solder+flux+pen&dpPl=1&dpID=31u2-ijUmFL&ref=plSrch

Solder:

https://www.amazon.com/gp/aw/d/B00030AP48/ref=mp_s_a_1_3?ie=UTF8&qid=1525828185&sr=8-3&pi=AC_SX236_SY340_QL65&keywords=solder

I typically use 60 40 0.031 lead solder, which is cheaply available from amazon, including prime. One of these spools will last a very long time for only $30. These tubes are available for smaller quantities.

The main concern with solder is the flux fumes, which are actually worse with higher temperatures and lead free solder. One simple solution to solder fumes is a pc fan with some sort of filter on it, such as this one. I made one for around $4, and it works very well. It also helps to mount it on some sort of arm, such as solid copper wire or one of these. There are many types of fume extractors that would work.

As for the soldering iron, I use a weller wes51, but a hakko fx888 is also good.

Soldering iron, $9. Solder, $2.50. Some shrink tubing, $3.50.

This will do for 90% of casual hobby electronics, for a grand total of $15. If you enjoy it, you'll upgrade the iron (and still be able to use solder and heat-shrink).

You need to learn to solder, but it's easy.

This is my go to list for what you need for soldering:

hakko soldering iron w/ diagonal cutters $91

hakko diagonal cutters $4.37

solder $7

solder sucker $6

solder flux $8 check digikey

solder wick $7 check digikey

wire strippers $10

helping hands $7 check harbor freight

check for lower price

One of the hakko clone stations paired with some genuine hakko tips is probably a good compromise on price/value. Maybe someone else that's from the UK could suggest something different that's also affordable there.

Soldering iron for sure. If you're serious about it then I would get a large one (60-70 watts) and a small one (30 watts), the pencil type are cheap. Or just get one 40 watt.

Get good solder, seriously, you'll fucking hate life with shitty solder. I used to be able to buy it locally but the mom 'n pop store went out of business, and I've tried every solder at Home Depot and they all suck. Both of these are good, however, and you should be able to solder as small of a wire you want with that.

I use 67g zilents and they are pretty good. I like them. Personally, I'm currently using T1 switches, but these are pretty loud.

As for soldering, what equipment do you have right now? All you need is a steady hand, a good soldering iron/station and lots of patience.

And make you sure you have the right solder too - this is highly recommended - it's thin solder (0.031 inch diameter) - and 60/40 - do not get lead-free solder. it just doesn't work as well

https://www.amazon.com/KESTER-SOLDER-32117-24-6040-0027-Diameter/dp/B00068IJPO/

Don't use the new solder. It's crap. Use real lead/tin 60/40 solder. Thankfully, Amazon has us covered.

https://www.amazon.com/KESTER-SOLDER-24-6040-0027-Stand-Diameter/dp/B00068IJPO/ref=pd_lpo_201_tr_img_3?_encoding=UTF8&psc=1&refRID=W9A6T0888VBDR9442A5N

That teleporter is halfway built!

http://www.amazon.com/Kester-Rosin-Core-Solder-Spool/dp/B00068IJPO/ref=sr_1_1?ie=UTF8&qid=1421246616&sr=8-1&keywords=kester+44+rosin+core+solder

I've been soldering for decades and I have never found a lead-bearing solder that worked better overall. I use 0.031" for through-hole work, 0.020" or even 0.015" for SMD and touch-up. The flux is fast-acting enough that I can use Weller 800F tips and a quick-in-quick-out soldering technique, completing the joint before the heat can spread far. In any case, you get best results when you touch the tip of the solder to the junction of iron and wire, aimed such that the flux spits straight into the joint as it boils.

add: Using 63/37 rather than 60/40, you minimize the paste period where the lead has chilled but the tin is molten, thus reducing the chances of a cold solder joint due to movement.

> The 63/37 is a eutectic alloy, which:

>

> 1. has the lowest melting point (183 °C or 361 °F) of all the tin/lead alloys; and

> 2. the melting point is truly a point — not a range.

-- http://en.wikipedia.org/wiki/Solder

Good background info: http://www.kester.com/knowledge-base/faq/

IMO you can use whatever iron you want, but spend money on good solder. I like Kester 44 63/37. 63/37 means 63% lead, 37% tin, which is the "eutectic alloy" for solder. That means it's the lowest melting temp you can achieve (less heat on the joints is a good thing), and maybe more importantly, it melts at one precise temperature, while most solder melts at a range of temps, and within that range it is a kind of goopy solid that's hard to work with. 63/37 totally alleviates that scenario.

Kester 44 is great in particular because it has a huge rosin core which means a lot of flux on the joints, which lets solder flow into the joint easily and avoids oxidation.

My recommendations, and what I have used for a long time. Really don't go super cheep on your iron, you will regret it:

Weller WES51

Long Conical Tip Really necessary if you are going to be building things with small components.

Kester 44 Rosin Core Solder 63/37 .020 the link is to a full pound which you might not want to spend the money on right away. The price seems to have doubled in the last 3 months at amazon for some reason. But plenty of places sell Kester Solder

Honestly, I'd get a cheap solid chinese one off amazon, with a proper stand. The SEEED has a bit of an issue staying up to temp.

I've had one of these for a few years, and it's been pretty decent. Half the price, more options, and a much better stand.

A portable iron has more problems than it solves, usually. A nice station is almost always better.

The Weller station should work just fine for you. I have the Aoyue 936 and really love it. It also comes with a spare heating element should the pre-installed one go bad. It also has temperature control rather than wattage control, which I like.

This is a great first kit to get you started. I bought this exact one and built like 5 keyboards with it before I upgraded to a nice Hakko station.

The one thing that you do NOT want to skimp on, though, is desoldering braid. A lot of newbies make the mistake of not planning for mistakes. This kit comes with a cheap desoldering pump, but it is garbage. It might seem pricey, but this stuff is the best desoldering braid on Earth, and will last you a long time. If you even have to desolder so much as a single switch, you'll be glad that you bought this stuff.

Outside of that, as /u/clee290 said, you'll want to watch some soldering videos. It's not terribly complicated stuff, but you'll want to have an idea of the basics to prevent common mistakes.

I’m using

Hot Max 500G Big Max 500,000 BTU... https://www.amazon.com/dp/B00282LP34?ref=ppx_pop_mob_ap_share

will pair it with a well insulated metal trashcan, one or two layers of ceramic blanket with satanite, and fire bricks at the bottom. Could it get as high as 2300 F? I’d rather not buy a higher range temperature gun if I don’t need to. Thanks for the help.

Actually I do have a flamethrower

https://www.amazon.com/dp/B00282LP34/ref=cm_sw_r_awd_mOHaub1087HP0

so that could work. But I would most certainly die in the attempt! Horribly.

Right fucking here, boss.

I've done cast iron on an 1800W induction top. I can get that thing in the 600 range, if my IR thermometer is to be believed.

I'm not talking about a plumber's torch like the TS8000. I'm talking about a "weed burner".

One like this https://www.amazon.com/Hot-Max-500G-Propane-Torch/dp/B00282LP34/ref=sr_1_7?keywords=weed+burner&qid=1569026185&s=gateway&sr=8-7

Edit: I want to say that these flamethrowers are incredibly powerful and loud. They sear a steak in 5-10 seconds per side. They're also so loud, that it's kinda awkward to use. I'm just waiting for the day for one of my neighbors to come over and ask me WTF I'm doing and why am I running a jet engine in my back yard.

If you don't want to use toxic chemicals, try this bad boy for cookin' them to the ground: Hot Max. Makes weeding actually fun! Then, to keep them from coming back, Sprinkle some of this around: corn gluten. Completely non-toxic, prevents any seeds from sprouting (not just weeds so be careful if seeding), and lasts for several years.

Propane and natural gas burners are not compatible. Make sure whatever your source of fuel matches the burner you buy.

These are good for raku temperatures and beyond.

https://www.amazon.com/gp/product/B006NXASIC

https://www.amazon.com/gp/product/B00282LP34

Unless you're going to do a lot of desoldering then just get a copper wick.

Yep you're correct.

When soldering there are a few basic things you have to consider. The main idea is that you want to heat up the wire and the contact point to the point that the solder will "wick" to the parts. You don't want to just melt the solder on the iron itself and have it drizzle on the parts.

Here are some other basic tips I wish I had been told when I was learning to soldering electronics in no logical order:

But most of soldering is just practice. It's a pretty easy skill to get proficient at. After a few projects it'll be almost second nature.

Don't use lead-free solder, that was my lesson a few days ago. And I was pretty okay with it... but man, the 60/40 stuff is night and day difference with its lower melting point.

Use flux. Like a lot of it. Get one of the containers of it. Anything you're about to touch the soldering iron to, dip it into the flux or wipe flux onto it. I always forget this and when I remember, again, huge difference, things are much easier. I don't understand how it works, I think it conducts heat, but it definitely helps. Even if you have flux-core solder, do this, the flux inside the solder is not enough.

Keep solder on your iron. Any time you need to heat something, put some solder on the iron (if it doesn't already have some) and THEN touch it to that thing. Don't just touch it dry onto something. The solder on the iron is called a solder bridge and it vastly helps heat up whatever you're trying to heat.

When it comes to soldering tips, the bigger the better. And don't use the stupid cone ones; get one of them with one or two flat sides to it. Obviously you can go too big, but the bigger it is, the more surface/mass to conduct the heat from the iron to the thing you're heating.

Preferably get a temperature controlled iron. I heat up things like bullets (non-sensitive components) to 410 C and sensitive things like my ESC wires I drop down to 370. Don't hold it for more than about 10 seconds, if you need longer you're doing something wrong, and the heat is being conducted down the wire onto the sensitive components. You can hold it to the bullet as long as you want though. If the flux is turning black and chunking up your solder, the iron is too hot (it's burning the flux).

Pre-tin wires and bullets. Might be best to find a youtube video. For wires, basically put some solder on the very end of the wire bundle, hold your iron there and try to push your solder into the side of the bundle. When the bundle gets hot enough, you will be able to just push solder into the bundle and it'll disappear as the bundle sucks it up. Once you fill the bundle it'll collect on the outside and that's when you know to stop. For bullets, just put some solder in it and hold the iron until the solder sticks to the edges (sort of makes a U shape), that's when you know the bullet itself heated up enough. Make sure to put enough solder in the bullet, I usually underestimate so I put a little more than I think I need and it turns out alright.

Oh and learn what a cold solder joint is. Don't do it. You can't just heat up solder in the bullet, and then shove your wire into it. Always pull on your connection (HARD) after you solder it to make sure you didn't make a cold joint. But usually you'll know when you made a proper joint, the heat should be adequate and the solder should flow.

These have been my latest lessons learned, hope it helps. Soldering bullets is still a HUGE pain.

edit: (I keep editing) -- make sure to get one of these brass sponge things, basically you shove the iron into it a couple times and it 'wipes' the old solder/flux off the tip, then you tin the tip again (i.e. just put a thin layer of solder on the soldering iron). Do this between everything, and also when you're done with your iron (don't let it cool messy). And optionally get one of these too, it's a little jar about the size of a US quarter and it seems like it's full of rock or something, but you wipe your iron on it and it melts a little, cleans the iron and lightly tins it. I use this if the iron is messier than the brass can handle, or solder doesn't seem to be sticking to the iron.

I think that's all for reals this time.

No, she was sanding it, which removes the plating and destroys it. You clean a tip with something like this, or failing that, a wet sponge or paper towel. This is what the tip of a clean soldering iron looks like, and this is what it looks like when it's working properly (apologies for the focus on the second one, I don't have enough hands).

Never use abrasives on the soldering iron tip. First, use a wet sponge to wipe off the tip before soldering. If there's krud building up that doesn't come off with the sponge, wipe it on a cleaning wire. If the tip gets really bad, it can often be restored with a chemical tip tinner.

Like other posters have said, to make the tip last longer leave a blob of solder on the tip when you are done soldering, wipe it off before starting soldering. And turn the iron temperature down when not using (I turn it down to 450F when it's idle).

It'll be blackened, solder won't stick to it, and it'll have poor heat transfer.

Properly tinning and caring for your tips is one of the first things you should learn--use the bronze puff (or less ideal sponge) to clean off flux and excess solder during use.

If it's a good quality tip, the black stuff will only be burnt on flux, rather than full oxidation of the cladding (at which point, you should replace it). To quote myself from another post (n.b. don't use sand paper to try to clean up your tips):

> I use a scour pad (keep a small part of one in your toolbox, inside a ziplock) on my tip when it gets really carbonized, and then follow it up with Weller tip tinner / activator. As many others are saying here, a low-abrasive bronze puff is better than a damp sponge for cleaning your iron when in use, since it can better wick solder and doesn't subject the tip to as much thermal stress.

Thanks! Glad I could be helpful.

The reflow station/solder paste is just awesome. The results are so much better than the hand soldering I tried to do initially.

My tips for the hot air reflow- Keep the air speed low (I do 1.5 - 1.75 speed @ 350c), you don't want to send the components sliding around the PCB. You only need a tiny dab of solder paste on a tinned board, otherwise you'll end up with little balls of solder where the excess collects. These can be knocked off with tweezers, but you should be careful to check for them as they can cause shorts.

I forgot one of the most useful tools out there! This is maintained by one of the FB Euro SMD DIY Noobs members.

This is the repository I use for .hex files. It's maintained by another SMD Noobs member.

These are the tweezers I use for handling SMD parts.

You'll also want a flux pen! Flux pens are wonderful.

I'd also suggest a magnifying glass or jeweler's loup of some sort for inspecting the PCB for shorts. I use a 10x loupe.

Here's a pic of my current workspace in an unusually clean state.

My SMD component filing technique. A work in progress.

Feel free to let me know if you have any more questions.

Flux Pen

Here is the flux pen I am accustomed to using. It works well for most applications, and is fairly inexpensive.

From my research that I've done in the past this indicates:

1 - bad ribbon connection.

2 - the CPU in the main board (t-con) is going bad.

3 - the cpu has developed some microscopic solder cracks.

Open it up and check for faulty ribbon cable connections. They are fairly easy to take apart just remember where everything goes.

If messing with ribbon cable didn't do anything, and since we may be looking at a bad main board anyway, you may try to reflow the main board CPU.

There are different ways to go about doing this like sticking it in kitchen oven at a certain temperature but the easiest would be to use a heat gun with no clean solder.

Here's an el cheapo heat gun that you can try with out breaking the bank.

http://www.harborfreight.com/1500-watt-dual-temperature-heat-gun-572-1112-96289.html

Here's a no clean solder pen:

https://www.amazon.com/SRA-Soldering-Flux-Low-Solids-No-Clean/dp/B008OC0E5M

Youtube "heatgun CPU reflow" to see what I'm referring to.

As /u/Harakou commented, make sure to have desoldering materials. But for desoldering several switches at a time, I had trouble making progress with a regular solder sucker (the braid is very useful for small scale rework). So I bought a desoldering iron for several Planck and Ergodox rebuilds.

And to add to /u/deaconblue42 , a flux pen helped me a lot whenever I struggled to get good wetting action (watch the videos, it's a thing).

You wanna sear your steaks with a heat gun? I've melted butter and the like with one, I've even heated up food out of the fridge with one, so it should work. This is the one I used, on the highest setting. When I read the output temp with a thermometer it showed about 550 degrees F. https://www.amazon.com/gp/product/B00EU2T8GG/ref=oh_aui_search_detailpage?ie=UTF8&psc=1

+1 for the Hakko FX888D-23BY

Some solder wick and a desolder pump is something else I would add. Also a cheap tip thinner for a noob (like me). Helping hands are cheap and can be useful. Also a cheap variety pack of tips. Nothing expensive till you are comfortable with keeping them clean and tinned.

These are all things I bought when I purchased my Hakko FX888. All have been useful.

Desolder Pumps and Wick

[Tip tinner] (https://www.amazon.com/dp/B00NS4J6BY/ref=cm_sw_r_cp_apa_i_k1kZDbJ5TS5Q6)

Helping hands w/magnifying glass

Various Tips

Hakko FX888D-23BY

All of this cost me $146 shipped. Right now, it'll all total to $139.83 shipped if in the US

LOL, that last part, it's happened to all of us though being honest. :P Anyways u/superuser41's suggestions are spot on. I use a Hakko FX888D myself & love it, very nice station for the money IMHO. Never used that particular sodapult but they are well regarded in the community.

Edit: This is a good tip for soldering switches & LEDs (my personal fav size/type for it). You may want to grab a few, it looks like the linked bundle only comes with one tip. Also this is a high quality solder in the right diameter for soldering switches/LEDs. This is good solder wick, This is a good flux, & I always recommend getting some tip tinner.

Get yourself some tip tinner.

I havent built that model but to answer your second question...Be cautious of build guides (or lack thereof). The one you linked has a really good guide. Step by step, clear pictures, and in color. So far, I've found Befaco, AI Synthesis, and Trogotronic to have really good guides.

Also, take your time. Its better to go slow and be sure of your work than rush. Tape! Tape helps me a lot by holding small pieces in place. If you can, get this circuit board holder. I got this magnifying headband for free (that style, not that specific one) and its been really helpful as well.

Here are my go to recommendations for beginners.

Trogotronic VCA

Trogotronic Power System

AI Synthesis

This maybe, or this. I spent no more than that on mine and it's seen me through 6 builds/rebuilds so far, and it's still working.

A proper soldering station is nice, but you can definitely get by with cheap stuff, especially if you don't plan on using it a ton.

Tabiger Soldering Iron Kit 60W 110V-Adjustable Temperature Welding Soldering Iron with Tool Carry Case https://www.amazon.com/dp/B01H1IFT54?ref=yo_pop_ma_swf

Works great. Most everything you need is included.

If you've got a nice hefty budget, if recommend a Hakko soldering iron. If you wanna go cheap, make sure you get one with a temperature control. [Here] (https://www.amazon.com/dp/B01H1IFT54/ref=cm_sw_r_cp_apa_YA2CzbK19K8S7) is a cheap one that would do the job. I've used that model to build two let's splits. Go to YouTube and watch some "how to solder" videos

Just a heads up, the REV-C to GND jumper wire won't fix all of the issues only seen on the 40-pin models.

Search eBay for a "40 pin type b" cable. It's a revision that fixed quite a few problems ... and one that you haven't seen yet, awful pixel retention / ghosting.

If you go with the "type b" cable, you won't need the jumper connection pictured.

Now, onto your question ...

There's an issue with the way the jumper cable was prepared. The solder point on the REV-C looks like it's touching several pads, not just the intended. To fix what's pictured ...

Again, all of this is done to fix what I'm seeing in the picture, but this won't fix the next problem, ghosting and pixel retention.

Grab a "type b" cable.

Also, I learned how to solder from watching endless YouTube videos. Here's a good one from Ben Heck.

Thanks for the invite! I love barbecue. 🤤

I don't have any kit recommendations, but you'll need:

That covers everything that you'd basically need for a job like this.

I think a lot of people have trouble because they don't have a hot clean tip. My friend who "can't solder" has a 20+ year old soldering iron with a corroded tip. I use a wet sponge, cleaning wire, and tip tinner interchangeably to keep it clean as I go.

Also having one of those magnifying glass/alligator clip holders is extremely helpful.

One more question... do you personally use wicks or a pump for desoldering? If you prefer a pump, can you recommend one?

Might go with this newer version because it comes with more tips.

Heres my baby .. ZERO COMPLAINTS

http://www.amazon.com/gp/product/B006FA481G/ref=oh_details_o09_s00_i00?ie=UTF8&psc=1

I have an aouye 968A+, it has very precise controls for both the heat gun and pencil. great value. amazon and sra soldering have complete kits including parts, it's better to buy from them than on ebay.

http://www.amazon.com/gp/aw/d/B006FA481G

Not the one I have...

http://www.amazon.com/gp/product/B006FA481G/

Heated PCBs are hard anyway because they are a weird combination of heatsinking and thermally insulative. If you are ever going to solder a second thing, just get a good Hakko or something. I have the analog version of the linked iron, and love it. I leave it at 350C constantly ... it gets to temp in like 20 seconds and holds it rock solid.

http://www.amazon.com/Hakko-Digital-FX888D-CHP170-bundle/dp/B00AWUFVY8/ref=sr_1_1?ie=UTF8&qid=1421772043&sr=8-1&pebp=1421772044939&peasin=B00AWUFVY8

Also:

http://www.amazon.com/SRA-Soldering-Flux-Low-Solids-No-Clean/dp/B008OC0E5M/ref=sr_1_1?ie=UTF8&qid=1421772121&sr=8-1&pebp=1421772121985&peasin=B008OC0E5M

I'd highly suggest you plunk down and get both. You'll feel like a wizard from now on with soldering. For the flux pen, just drown your connections, wire, pads, etc in flux before soldering. Within a very generous reason, you cannot overflux things, and it makes the solder actually behave like it should. It globs where it's supposed to, doesn't make those stupid little peaky points that bridge everywhere, and so on.

> along with a soldering iron to do repairs.

Totally agree. I would suggest any of the Weller pro series models(Indicated with the light blue chasis like the Weller WP35). Even their most inexpensive model is better than anything I have used off the shelf at Home Depot. Consistent tempuratures and fast heat up.

Additionally, I would also recommend a solder sucker and a flux pen. You could splurge for something like a Haako Desoldering gun which works great but unless you are doing entire board repairs the simple spring loaded ones work fine and costs considerablly less.

If you don't have any solder I recommend [63/37 Resin Core](Kester 44 Rosin Core Solder 63/37 .031" 1oz Dispense-Pak https://www.amazon.com/dp/B00AVLM4SO/ref=cm_sw_r_cp_api_xwuEybG623XFQ), don't need flux or anything with resin core, just the solder. GL!

Kester 44 63/37 is approximately the best solder you can buy for keyboard related needs, available in both 1lb spools and 1oz tubes. Yes it's a bit pricey, but solder is one of those things where you get what you pay for, and dealing with cheapo no-name solder can actually lead to damage to components.

Nothing expensive required. I suggest starting with a kit like this it contains a lot of the tools you will need for keyboards. The only change i would make would be to also get some Kester 44 solder like this. I'm happy to walk you through it via facetime or in person. Let me know.

I would recommend solder a little thicker than the other gentleman because with .5mm solder you'll be spending a bit more time feeding the solder than .8mm solder.

I solder at 270 °C. Temperature is more or less a preference (there are limits though).

Soldering keyboards doesn't really require any holding of the pcb. Perhaps you mean holding the solder? - Use your hands.

Edit: bonus soldering station recommendation: If you plan on doing a bit more soldering work in the future you might want to consider this cheap but decent soldering station. Only con is that it doesn't come with extra tips or tweezers etc.

If you already own a couple of customs, go Hakko or go home.

Pick that up, and some small gauge Kester 63/37, and you're good to go.

Check Craigslist for guitars that have electronic issues or are completely dead. For example I got an rg321mh that has a perfect neck and frets for $60. All I had to do was rewire a new input jack. Get a cheap solder pen and some 63/37 rosin core solder.

Wiring guitars is WAY easier then most people think. You can find diagrams for almost any production guitar/pickups.

Just make sure your frets, neck, and nut are good, that stuff is a pain to fix. The rest you're replacing anyways.

I just do a full rewire. Buy the following for a dead guitar: 1. CTS pots. 2. Switchcraft input jack and switch. 3. 22awg cloth sleeved wire. Use a multimeter to check pickups resistance. Or just get some guitar fetish pickups of your choice for a cheap option of new pickups. Then just do the full rewire following a diagram. Make sure to pre-tin your solder pen, the solder point, and your wire. Also sand the back of your cts pots for easier adhesion. Pickup a $5 helping hands from harbor freight to hold stuff to solder.

All this stuff will cost you around $50-60 with a cheap solder pen kit ($12 Amazon) and you will have enough wire and solder to do a bunch of guitars.

You will have a completely rewired guitar in less than 2 hours of work.

Here is links to solder pen, solder, and wire. The rest just lookup for your guitar you're gonna rewire.

https://www.amazon.com/Vastar-Soldering-Iron-Full-Welding/dp/B01712N5C4?ref_=fsclp_pl_dp_6

https://www.amazon.com/Gavitt-Cloth-covered-Pre-tinned-Pushback-Vintage-style/dp/B00JYJFE72/ref=mp_s_a_1_4?keywords=22+awg+wire+cloth&qid=1556147584&s=gateway&sr=8-4

https://www.amazon.com/Kester-Rosin-Core-Solder-Dispense-Pak/dp/B00AVLM4SO/ref=mp_s_a_1_4?crid=IRV7SJBS91YR&keywords=63+37+solder+kester&qid=1556147625&s=gateway&sprefix=63+37&sr=8-4

Indeed. This and this are perfectly adequate for an enormous amount of practice, and come to less than $40, delivered.

It's way, way better kit than what was available inexpensively when I got started.

For anyone reading this, a standard heat gun has a lot of uses, but is the great for efficiently cleaning the stock of cosmoline.

Edited a profile to get your settings about right, should help.

https://files.fm/u/bbeq5kqk

Also heat guns eat up strings, just use quick passes once the gun is up to temp, if you linger on a miniature for more than 2 seconds you'll probably start to get deformations.

https://www.amazon.com/Genesis-GHG1500A-Temperature-Nozzle-Attachments/dp/B00EU2T8GG/ref=sr_1_1?s=hi&ie=UTF8&qid=1524940417&sr=1-1&keywords=heat+gun&dpID=41o%252BjfZKenL&preST=_SX300_QL70_&dpSrc=srch

Genesis GHG1500A Dual Temperature Heat Gun Kit with Four Metal Nozzle Attachments https://www.amazon.com/dp/B00EU2T8GG/ref=cm_sw_r_cp_api_SerOBbD9N3VW3

Heat guns are cheap.

I think they might even be cheaper at Home Depot.

I highly recommend spending a bit of money to get an actual heat gun, as opposed to a hairdryer. They're not that expensive (here's the one I have for $19), and they blow MUCH hotter than hair dryers. The advantage is that you can just sweep them across the model and the strings will basically vanish before your eyes. With a hairdryer you usually have to hold it in place for a second which can result in the warping

Easy fix. Anyone saying to cut the loop off has never actually strength tested these loops.

Watch the end of this video.

To fix your loop instead of cutting it off, buy polyolefin tubing. 3-5mm should be about right.

Next, buy a heat gun.

Cut a short length of tubing, slide it over the end of your line, and waft the heat gun so the tubing shrinks and the line inside it liquefies but does not burn. Let it cool, then peel the heat shrink back off (use a pair of tying scissors to snip it and get it started so you can peel it).

It'll be good as new. You can also cut that one off and make another if you want a new loop. Fly lines have about 2 feet of level tip material to allow for this kind of cutting.

No knot is as strong as a welded loop. Welded loops were about 3X stronger on average than every knot I tested, sometimes more. Here is my original thread on the tests I did.

Here are the results of my strength tests for the Fly Rod & Reel article:

Knot Break Strength - Tested to failure with Boga Grip using 20 lbs. monofilament

|Knot | Test 1 | Test 2|

|---------|----------|----------|

|Nail Knot (5 Turns) | 10 lbs. | 10 lbs.|

|Albright Knot (5 Turns) | 12 lbs. | 12 lbs.|

|Doubled-Line Nail Knot| (6 Turns) 8 lbs. | 10 lbs.|

|Double Surgeon’s Knot | (20 lb. to 20 lb.) 14 lbs. | 18 lbs.|

|Castwell Knot | 13 lbs. | 12 lbs.|

|Welded Loop | 20 lbs. X 3 attempts (see video)|

Good question, and it pains me a bit that I have a small box of unused tools that were purchased when I began. I'm sure I missed a few things, but here you go:

If links weren't provided then I already had the item.

Get your self some tip tinner, which is usually a combination of sal ammoniac and solder paste. Use it sparingly-- only once your tip won't wet on its own after being wiped clean.

I recently bought one of these for myself and I couldn't be happier as a DIY hobbyist:

Hakko Dial type temperature limiting soldering iron FX600

I only use it for hobby stuff such as Quadcopters, 3D printers and electronics kits but it's way better than the 8watt USB powered I was using before.

Pair it with this and this and you should be good for a while and roughly within budget.

Check YouTube for soldering tutorials. Plenty out there.

Definitely tin the tip of the iron everytime you solder. I also use some of this to help keep the tip clean.

I know you don't want to go for a more expensive iron but my hakko iron is awesome and it really makes soldering more enjoyable. Worth the investment if you stay in the hobby.