Top products from r/Bladesmith

We found 36 product mentions on r/Bladesmith. We ranked the 136 resulting products by number of redditors who mentioned them. Here are the top 20.

1. Crescent Nicholson 12" Flat Double Cut Bastard File - 03762N

Sentiment score: 1

Number of reviews: 3

American Pattern Flat File, Bastard CutUsed By Machinists, Machinery Builders, Ship and Engine BuildersAlso By Repairman and Others Who Require Rapid Removal of MetalRectangular in Cross Section and Taper Slightly Towards Point in WidthDouble Cut on Sides, Single Cut on Edges

Show Reddit reviews

Show Reddit reviews2. Palmgren 2" x 42" Belt, 6" Disc bench finishing machine

Sentiment score: 0

Number of reviews: 2

1/3 HP, 120/240VAC motor, 3.5/1.75 amp, 3500 RPM2-Inch x 42-Inch Belt speed 4400 SFPM6-Inch PSA abrasive disc, 3500 RPMBelt arm operates vertically and horizontally

Show Reddit reviews

Show Reddit reviews3. BernzOmatic Basic Use UL2317 Brass Pencil Flame Propane Torch Head

Sentiment score: 0

Number of reviews: 2

Manual start (light with a Bernzomatic Spark Lighter, sold separately)Basic pencil flame for small diameter soldering, thawing, melting and heat applicationUse only with propane fuel, such as the Bernzomatic 14.1 oz. Propane Hand Torch CylinderBrass construction for durabilityFlame control valve eas...

Show Reddit reviews

Show Reddit reviews4. MG Chemicals 415 Ferric Chloride Liquid

Sentiment score: 0

Number of reviews: 2

Copper etchantMore aggressive than persulphate alternativeCan be stored and reusedReady to use solution designed for etching printed circuit boards and other metalsRecommended for use with M.G. Chemicals professional etching process kit and M.G. economy etching process kit

Show Reddit reviews

Show Reddit reviews5. Dia-Sharp Bench Stone

Sentiment score: 1

Number of reviews: 2

Crafted from the highest quality materialsBuilt for performance and durabilityMade in United StatesDouble-sided blade sharpener with monocrystalline diamond surfaceCoarse diamond on one side to restore a neglected edge and fine diamond on reverse side for a razor-sharp edgeDiamond grits clearly mark...

Show Reddit reviews

Show Reddit reviews6. Wayne Goddard's $50 Knife Shop, Revised

Sentiment score: 2

Number of reviews: 2

Brand New & Factory Original!

Show Reddit reviews

Show Reddit reviews7. O1 Tool Steel Sheet, Precision Ground, Standard Tolerance, Inch, ASTM A681

Sentiment score: 2

Number of reviews: 2

O1 tool steel has better machinability than A2 tool steel, and must be hardened in oilMeets ASTM A681 specificationsGround with high precision to the specified shape and sizeStandard tolerance

Show Reddit reviews

Show Reddit reviews8. Flat File Sanding Stick With Replaceable Abrasive Strips For Sanding Shaped Objects on Wood and Some Metal. Ideal For Woodworking, Furniture, Restoration, Cabinets, or Automotive Use

Sentiment score: 1

Number of reviews: 2

Quit using a sandpaper wrapped tongue depressor or emory board to get into those tough to reach areas. The Sanding File works just like a normal file does. Thats what makes this tool so unique! It gives you the look and feel of a tool that you already know how to use and it feels just right in your ...

Show Reddit reviews

Show Reddit reviews9. Fire Brick - 2 Pack

Sentiment score: 3

Number of reviews: 2

FIRE BRICKS - Lightweight heat resistant surface. Includes 2 bricks.MULTIPLE USES - Use to fire PMC+, PMC3 and silver soldering projects.WITHSTANDS HIGH TEMPS - Built to withstand temperatures up to 1600°F.EASY TO CUT - Cuts easily with a saw.DIMENSIONS - Large surface - 9" long x 4-1/2" wide x 2-1...

Show Reddit reviews

Show Reddit reviews10. Knives and Scabbards (Medieval Finds from Excavations in London) (Volume 1)

Sentiment score: 2

Number of reviews: 2

Boydell Press

Show Reddit reviews

Show Reddit reviews11. US Stove FBP6E FireBrick for Stoves, 6-Pack

Sentiment score: 0

Number of reviews: 2

Replacement bricks for firebrick linersDimensions: 4-1/2 inches x 9 inches x 1-1/4 inches6 bricks per packageSuitable for use in ovens and kilnsFor any brand of wood or coal stove that uses this standard-sized brickNot for outdoor firebrick usage

Show Reddit reviews

Show Reddit reviews13. K Kwokker 15Pcs Masonry Drill Bits Set 3mm to 16mm for Glass, Ceramic, Marble, Plastic, Brick, Tile, Wood, Tungsten Carbide Paddle Shaped Tip Triangle Alloy Professional Masonry Bit

Sentiment score: 0

Number of reviews: 1

☺[15 PCS MASONRY DRILL BITS 3MM TO 16MM] come in a nice storage case. 16mm, 14mm, 12mm, 10mm, 8mm, 6mm, 5mm, 4mm, 3mm. There are multiple 9 sizes that will help in drilling by starting with the smallest bit and continuing to the size needed. Meeting your various needs.☺[K KWOKKER MASONRY DRILL B...

Show Reddit reviews

Show Reddit reviews14. The Woodworker's Guide to Pricing Your Work: How to Calculate the Value of Your Time, Materials and Craftsmanship to Make Money from Your Woodworking

Sentiment score: 1

Number of reviews: 1

Used Book in Good Condition

Show Reddit reviews

Show Reddit reviews15. The Medieval Sword in the Modern World 2nd Edition

Sentiment score: 1

Number of reviews: 1

Show Reddit reviews

Show Reddit reviews16. Nikey Sports Shorts (S, Red)

Sentiment score: 1

Number of reviews: 1

DSM 5 Abnormal Psychology

Show Reddit reviews

Show Reddit reviews17. The Master Bladesmith: Advanced Studies In Steel

Sentiment score: 1

Number of reviews: 1

Used Book in Good Condition

Show Reddit reviews

Show Reddit reviews

there is a book called 50$ knife shop that would be a good start. ABANA also has a level one beginning blacksmithing project guide. I would recomend trying that. its helpful.

as for the cheapest and dirtiest way to forge a knife, take a leaf spring or coil spring heat it up to orange color smash it flat on a flat hard surface (an anvil), forge a point on one end and a tang (handle) on the other. you can attempt to forge bevels too, but that part is hard to do correctly. it is absolutly necesary to beale to forge flat and straight. this is also hard to do. you can grind/ file a bevel from a flat, but you cant grind/ file something from crooked to straight.

once you have a straight flat forged to shape blade you take it to the grinder to remove scale. this can be done with a hand grinder or a belt grinder, but scale will eat belts fast!!! so a hand grinder is more cost efective. with the scale removed you are ready to grind/ file your primary bevel. No grinder? then clamp your blade to a 2x4 and get at it with some files. first establish a bevel then draw file it flat. (remember when draw filing right hand pushes and left hand pulls) once you have the blade filed its time to sand all those ugly marks out. i sand to 220 or so then heat treat...

heat treat... use simple steel like OTS (old truck spring/ 5160) heat to nonmagnetic then quench in warm canola oil. take it out and check with a file. it should slide across it like glass. if the file dosent bite you have a hard blade. now go temper it at around 400 deg for 2 hours twice. (4 hr total)

now you have a heat treated and tempered blade. you can sharpen it and test it now. file or grind your final bevel then sharpen on a stone. go chop some 2x4s and then try to cut some paper. if you got a good edge you should be able to chop multiple 2x4s and still have a sharp blade. if the edge chips or rolls something went wrong. go rebevel the edge and re sharpen. test again. Chips mean the edge is too thin or HT didnt go right. fix your problems hear not later. make a good preforming blade before you make it pretty.

now make it pretty, back to hand sanding. start at 120 and work your way to 400 or so. make sure to completely remove the marks form the previous grit sand paper. before moving to a finer grit. careful not to cut yourself when hand sanding. your blade should be razor sharp by now.

in all honesty id start with stock removal and if you still want to forge knives build up to it. for me forging is easy and fun. its the stock removal part thats the hard work. if you dont mind the stock removal part you will be a lot less frustrated...

You've thankfully got a lot of resources available online to help get you started. A good beginners tutorial can be found here on how to make your own custom knife from scratch with minimal equipment.

I tend to use Jantz Supply for a lot of my supplies including steel and kydex.

I'd highly recommend joining up for free on Blade Forums and browsing around the shop-talk forums. Tons of useful information by people that are just beginning and people who've been doing it for decades.

There's really tons of material online to help you figure out which steel to use. If you're just starting, I'd recommend sticking with something simple like 1095 high carbon, maybe 440C stainless. Here is a surprisingly good article written about it from an unexpected place. If you get the chance, pick up this book: The Master Bladesmith by Jim Hrisoulas. It's practically the knife-maker's bible.

Good luck and don't hesitate to ask questions!

Need a hard backing and some way to keep your sandpaper pulled as tight as you can. I have one of these and it works pretty well but I also made sort of a hand sanding block out of some oak with some u-bolts I can tighten down. It's also important have fairly clean lines going into hand sanding.

Depends were you live and it may take a visit to the place to see what they really have. I found a local store that had tool steel, O1 and W2, in both round bar and flat bar for reasonable prices BUT that isn't listed on their website. They also had a bunch of small cut off pieces of various metals for art projects which was really handy as well.

I know you didn't want to buy on line but Amazon has O1 with free shipping. Might be able to get a better deal locally if you look around.

I like this one for woodworking. I'd believe there is some good crossover: http://www.amazon.com/Woodworkers-Guide-Pricing-Your-Work/dp/1558703721

I don't have one for founding a small business off the top of my head. Go to your local library and your town probably has an office for businesses. I know that where I grew up offers classes, have meetings, and help people get started by informing them of local resources.

As /u/Ermott stated, if you've got a few years of free time, there is no shortage at all of information to be found online.

If you specifically want a book for reference, here's the list. (I own and have read, and re-read every book here.)

Stock removal knife macking -

Wayne Goddard's $50 Knife Shop, revised

How to Mack Knives, by Barney and Loveless

When you're ready to move up a few notches in complexity -

The Tactical Folding Knife, by Terzuola

If forging is more your thing -

The Complete Bladesmith, by Hrisoulas

An overview (and extremely interesting) look at how different modern mackers go about macking knives -

Blade's Guide to Macking Knives

And finally, the condensed Q&A for everything the aspiring knife macker could ever want to know -

The Wonder of Knife Macking, by Goddard

The second edition of this books has mixed reviews centering on poor editing, I've read and recommend the first edition, though slightly dated, for it's solid insight into so many areas of knife macking.

I hope this helps you, don't forget to come back and post photos of the knives you mack!

would these work well for building a forge out of? I'm not finding them in town so I think these for $15 (+$5 shipping) would do well for me if they are the correct type that I'd need.

Your prompt reply would be greatly appreciated.

I have toyed with this idea too, but I think a better option would be to make a larger forge with fire bricks like this one:

https://www.amazon.com/Delphi-Glass-Fire-Brick-Pack/dp/B00JMH53GS/ref=sr_1_13?ie=UTF8&qid=1498066584&sr=8-13&keywords=fire+brick

and make a frame out of angle iron or whatever to keep all the bricks together and secure the torch in position.

> So what you're saying is

Yep, pretty much exactly that.

I suspect corset ribbon would be possibly a little thin, at least going by most of the ones I've known, I originally used to bind up just with cord, but it leaves an impression in the leather, that can be seen through the outer when its really thin. the widest ribbon you can get easily is probably the way to go, so it spreads the tension over the whole thing, and that prevents marking.

for long sheaths, generally the liner either goes up to about 1/4inch / 6mm from the top, and the outer face rolled round, or they both go up all the way... the finishing is a bit of a debate - some the outer is skived and rolled, some the two are the same, and sewn together with a stitch to hold them together. I'm not sure there's a universal standard though.

some of the originals, by the way, have little cubes of leather underneath for raising, to make bumps.

though they're medieval, the principles are the same, and this book's excellent: (so many ideas!)

https://www.amazon.com/Knives-Scabbards-Medieval-Excavations-London/dp/1843833530

thoroughly recommend it.

For earlier period, 10-12th C, when most sheaths are single-layer, there's also this report from the York excavations:

https://www.yorkarchaeology.co.uk/wp-content/uploads/2015/05/AY17-16-Leather-and-leatherworking.pdf

those two should keep you busy for a while (between trying to wrangle the argumentative horses!)

http://www.amazon.com/Precision-Ground-Annealed-Thickness-Length/dp/B00CZDPAI2/ref=sr_1_fkmr3_1?ie=UTF8&qid=1421860628&sr=8-1-fkmr3&keywords=starrett+o-1+tool+steel+precision+ground

Here you go sorry I'm a little new to reddit I haven't quite figured out how to post tiny links like the other guy. Also for small-med size knives basically 10 in. and under I really like 3/32 for something bigger like a chopper go 3/16-1/4 in.

You can get a cheap small vise for $5-10 at a flea market. I got a really nice old vise for $25 at a tool swap meet and it wasn't the old one. If you have a tool swap in your area it's worth going to. On CL it seems everybody thinks an old vise is worth $200.

Large Nicholson bastard file will get you going. This one for instance. You'll need some way to clamp it down to your bench, you can't do much with the blade clamped vertically in a vise.

A round file of some sort will be useful, but you can use a dowel and sandpaper in a pinch.

Lots of sandpaper. You want the wet/dry stuff (not so much to use wet, but because it holds up to steel better). Get lots of 100 grit, lots of 220, some 320, and some 600.

Watch CL like a hawk for a 2x42 Craftsman belt sander. I got mine for $35. $50 of belts later and you've got yourself a versatile grinder.

Ok so alot of creating a blade from this point is sanding and polishing, and alot of doing it well comes down to technique. Technique mostly revolves around holding the blade at the right angle to the belt and doing so consistently. By far the best book I know of for sword makers (which I am) is this one here (not written by me but the definitive guide as far as I am concerned): https://www.amazon.com/Medieval-Sword-Modern-World-2nd/dp/1481891472/ref=la_B00A6X16X6_1_9/131-5853081-3985969?s=books&ie=UTF8&qid=1493741383&sr=1-9

How many of these bricks do I need? is one layer of these bricks fine? Can I use clay bricks for the main shape of the forge than us a layer of these brick on the inside?

http://www.amazon.com/US-Stove-FBP6E-Firebrick-6-Pack/dp/B00XC1YCTY/ref=pd_sim_201_8?ie=UTF8&dpID=51s-v5jHLyL&dpSrc=sims&preST=_AC_UL160_SR160%2C160_&refRID=0HMWC81VMBVWSNTNZ68H

Do I need thick ones?

http://www.walmart.com/ip/46056973?wmlspartner=wlpa&adid=22222222227033760275&wl0=&wl1=g&wl2=c&wl3=88146674568&wl4=&wl5=pla&wl6=122345140608&veh=sem

I wear nitrile gloves while sanding, and the blade went right from sanding, to a cotton cloth, to the bath. The steel is O1 from Jantz, so I trust that, and the bath was made using this.

I haven't sanded it other than a water and cloth rub down, because I am still debating if I like the look.

If I wanted to make a propane forge could I use this propane head ( http://www.amazon.com/gp/aw/d/B00008ZA0C/ref=pd_aw_sbs_2?pi=SL500_SS115&simLd=1 ) and just attach it to the side of the forge or do I need something like a trigger start torch ( http://www.amazon.com/gp/aw/d/B00008ZA09/ref=pd_aw_sbs_3?pi=SY115&simLd=1 )?

I know this is a dumb question but I'm on a budget for my starter setup

Or is this closer to what you're thinking?:

https://www.amazon.com/Kwokker-Tungsten-Triangle-Professional-Concrete/dp/B07QZRLD4L/ref=sr_1_3?keywords=tungsten+masonry+drill+bit&qid=1562896098&refinements=p_n_feature_seven_browse-bin%3A5485872011&rnid=3071213011&s=gateway&sr=8-3

Here is the mobile version of your link

Here is the mobile version of your link

http://www.amazon.com/Nicholson-03762N-Flat-Bastard-12-Inch/dp/B002M8TWOI/ref=sr_1_1?ie=UTF8&qid=1451716468&sr=8-1&keywords=double+cut+bastard+file

Hey I looked around and it doesn't seem to be sold anywhere anymore. https://www.amazon.com/gp/aw/d/B0006577HI/ref=psdcmw_552882_t2_B0064BLIUU this has the exact same specs just a different brand and has decent reviews.

This might be an option. One of the Q&A responders said it is basically the same thing as the Craftsman

https://www.amazon.com/gp/aw/d/B0006577HI/ref=psdcmw_552882_t1_B003J69ET0?th=1&psc=1

Here is the desktop version of your link

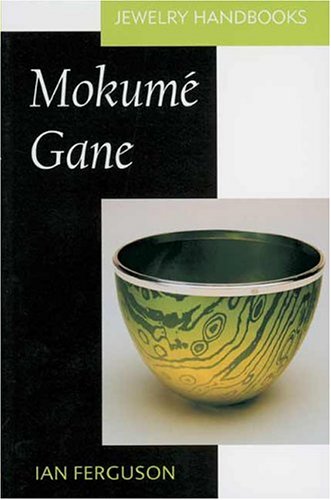

According to Ian Ferguson

Aluminum. . . "due to it's low melting point and ability to form low temperature phases, it is limited in its application with other metals."

https://www.amazon.com/Mokume-Gane-Ian-Ferguson/dp/0873499018