(Part 2) Top products from r/aviationmaintenance

We found 21 product mentions on r/aviationmaintenance. We ranked the 122 resulting products by number of redditors who mentioned them. Here are the products ranked 21-40. You can also go back to the previous section.

21. Streamlight 75813 Stinger DS C4 LED Flashlight with AC/DC Steady Charger, Black - 425 Lumens

Sentiment score: 0

Number of reviews: 1

Anodized aluminum construction with non slip rubberized comfort gripMulti function push button switch choose from high, medium, low or strobHigh for a high lumen, far reaching beam: 425 lumens; 26,000 candela; 322 meter beam; runs 3 hoursMedium for bright light and longer run time: 200 lumens; 12,00...

Show Reddit reviews

Show Reddit reviews22. 3M H10A Peltor Optime 105 Over the Head Earmuff, Ear Protectors, Hearing Protection, NRR 30 dB,Black, Red

Sentiment score: 1

Number of reviews: 1

Noise Reduction Rating of 30dBSuperior comfort, fit, and hearing protectionPatented twin-cup designRecommended for extremely loud conditions

Show Reddit reviews

Show Reddit reviews23. GROL Plus: General Radiotelephone Operator License Plus Radar Endorsement

Sentiment score: 1

Number of reviews: 1

Show Reddit reviews

Show Reddit reviews24. Introduction to Electronics

Sentiment score: 1

Number of reviews: 1

Used Book in Good Condition

Show Reddit reviews

Show Reddit reviews25. To Love An Aluminum Bitch: Stories & Lyrics of Aviation Maintenance & Adventure

Sentiment score: 1

Number of reviews: 1

Show Reddit reviews

Show Reddit reviews26. Aviation Mechanic Handbook: The Aviation Standard

Sentiment score: 1

Number of reviews: 1

Used Book in Good Condition

Show Reddit reviews

Show Reddit reviews27. Airframe Test Guide 2019: Pass your test and know what is essential to become a safe, competent AMT from the most trusted source in aviation training (Fast-Track Test Guides)

Sentiment score: 0

Number of reviews: 1

Show Reddit reviews

Show Reddit reviews28. Avionics Training: Systems, Installation, and Troubleshooting

Sentiment score: 1

Number of reviews: 1

Used Book in Good Condition

Show Reddit reviews

Show Reddit reviews29. Milwaukee 48-32-2100 Hex Shank 105 Degree Off Set 400 RPM Adaptor for Power Screwdrivers and Drill / Drivers

Sentiment score: 0

Number of reviews: 1

Magnetic Bit Holder: When you’re working in a crawl space, the last thing you need is your phillips bit falling onto the dark ground. This magnetized head will prevent that from happening360 Rotation: The flange can rotate along with your thumb, enabling a diverse set of hand positions for your ma...

Show Reddit reviews

Show Reddit reviews30. Scotch Rough Surface Extra Strength Painter's Tape, 0.94 in x 60 yd, 2060, 1 Roll

Sentiment score: 1

Number of reviews: 1

Designed for use on concrete, brick, stucco, and rough wood5-day clean removal leaves behind no damage or sticky residueVery strong adhesiveRecommended for use with or on lacquer coatingsBonds aggressively, yet has a smooth unwindSize: 0.94 in. x 60.1 yd.CREATE SOCIAL DISTANCING MARKINGS: Create box...

Show Reddit reviews

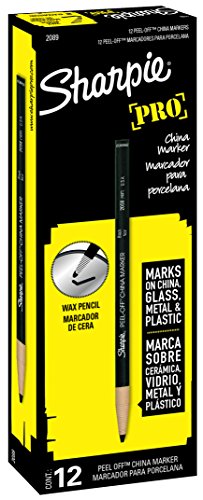

Show Reddit reviews31. Sharpie PEEL-OFF Marker China, China Marker Bullet, 12 Pack, Black (2089)

Sentiment score: 0

Number of reviews: 1

Create legible marks on metal, glass, china and a variety of other porous and non porous surfacesNo sharpening required : peal the paper wrapping back for more markerFade and moisture resistant wax pencil formula creates easy to see marksErases easily and cleanly with a damp clothIncludes: 12 Black ...

Show Reddit reviews

Show Reddit reviews32. CTA Tools 9435 24-Inch Long Flexible Shaft Mechanical Fingers

Sentiment score: 1

Number of reviews: 1

Featuring a 24-Inch LengthRugged All-Steel BodyIncludes Amazing Set of Four Powerful

Spring JawsDesigned for Easy and Quick Retrieval of Dropped Items from Tight AreasProudly Made in the USA

Show Reddit reviews

Show Reddit reviews33. IRWIN Screw Extractor Set, Hex Head, Multi-Spline, 25-Piece (53227)

Sentiment score: 1

Number of reviews: 1

VERSATILE: Remove broken studs, bolts, socket screws and fittings for high torque applicationsGRIPPING POWER: Aggressive left hand spiral design for extra gripping powerEASY-OUT STYLE: Spiral flutes embed themselves to increase grip as resistance increasesETCHED SIZES: Extractor size and recommended...

Show Reddit reviews

Show Reddit reviews34. Waekon 77203 Perfect Mate Round Terminal Probe Adapter Set

Sentiment score: 0

Number of reviews: 1

31 piece setIncludes banana plugs and 'T' adaptersLimited lifetime warrantyMade in USA

Show Reddit reviews

Show Reddit reviews35. Lisle 40200 Red 3/8" Magnetic Socket Holder

Sentiment score: 1

Number of reviews: 1

Organizes 3/8" fractional and metric sockets for easy storageFeatures 28 socket compartments for both standard and deep socketsMade of ABS plastic for durabilityOpen sign for easy identification of socketsMagnets hold sockets in tray and tray to steel surface

Show Reddit reviews

Show Reddit reviews36. Dewalt DPG59-115C Reinforcer Rx-Bifocal 1.5 Clear Lens High Performance Protective Safety Glasses with Rubber Temples and Protective Eyeglass Sleeve

Sentiment score: 1

Number of reviews: 1

Magnification diopter is molded into the polycarbonate lens.Hard Coat Lens which meets ANSI Z87.1+ StandardsHandgrip pattern on temple is ergonomically positioned for secure gripDistortion free lens provides fatigue free useSafety glass and Reading glass all-in-one with 99.9% UVA/UVB Protection

Show Reddit reviews

Show Reddit reviews37. STAEDTLER Lumocolor Universal Pen, Medium, Felt Tip, Permanent Marker, Box of 4 Assorted Color Pens, 1.0mm 317 WP4 (317 WP4 ST)

Sentiment score: 0

Number of reviews: 1

Write on ANYTHING: film, DVD/CDs, vellum, and oh yeah, paper. The permanent, quick-dry ink and super fine tip make these the perfect planner pensDry-safe ink and tip means even if the cap's been left off for days, it remains usable. You can just pick it up and carry on. Plus, no need to throw it awa...

Show Reddit reviews

Show Reddit reviews38. Rothco G.I. Type Mechanics Tool Bag with Brass Zipper, Olive Drab

Sentiment score: 1

Number of reviews: 1

Constructed of Heavyweight Cotton CanvasGenerous Main Compartment with 8 Inside Tool Organizer Pockets2 Outside Button Snap Pockets For Quick Access to Smaller ToolsEasy to Carry Canvas Straps for Transportation and a Full Length Nylon Zipper ClosureThe Durable and Functional Tool Bag Measures 11" x...

Show Reddit reviews

Show Reddit reviews39. Army Universe Heavy Duty Military Small Mechanics Tool Bag (11" x 7" x 6") (Black - Brass Zipper)

Sentiment score: 0

Number of reviews: 1

Made from Heavyweight Durable Cotton Canvas Material. Hard Bottom Protects Bag from Sharp Tools & Objects. Great to keep your things organized especially your small tools, drill, charger, nails and essentials.Outside pockets (approx. 11" W x 5" L) on both sides that has snap closures . Large inside ...

Show Reddit reviews

Show Reddit reviews40. Astro Pneumatic Tool 101 Mini Grease Gun

Sentiment score: 1

Number of reviews: 1

Mini grease gun with needle nozzleHeavy duty, lightweight and easy to handle needle nozzleHolds 3 ounces of lubricantCan be operated with one handWeight: 1 lb. (25 kg)Easily lubricates mechanism of air tolls w/grease type fittingsHolds 3 oz. of lubricantCan be operated with one handEasy to handle ne...

Show Reddit reviews

Show Reddit reviews

I’m an mechanic and and owner as well so I see both sides. Your intuition is right to get it out, it’s going to suck but the peace of mind is worth it.

Not sure if you already have some but some mechanical fingers will help you as it gets closer to getting it out.

The fuel will be a double edge sword, it will enable the float to float, but once it’s floating it’s going to move all over. My recommendation is once you get a visual on the float, try to grab it a bit with the fingers. If that doesn’t work get it positioned within the ribbed compartment of where the fuel cap is and drain the tank. Once the fuel is out of the compartment the float won’t be so easily moved and will be easier to grab with mechanical fingers, a bent coat hanger, what ever it takes to try to get the float close to the fuel cap.

In regards to draining the tank, obviously you can use the fuel drains but that will take forever and is kinda messy. I’d recommend purchase a siphon to speed it up. My favorite go to is the super siphon because it’s got a glass marble on the end to prime the line you just shake it up and down so there’s no drinking fuel and it has great flow once started. It comes in handy for jobs like this or say you decide to bring the extra person but your tanks are topped you can cleanly drain fuel into 5 gallon cans to shed the excess fuel. I know it says unavailable but look around the farm supply stores, home improvement stores, etc and you’ll be able to find one if you want that brand.

Not sure about the waterproof on the borescope you have. Depending on the unit it might not be waterproof but I’d check with the manufacturers specs to get an idea.

So the bad news will be if that float doesn’t float your going to have to go even deeper and remove sheet metal to find it. I imagine if your fuel tank indications were normal or at least somewhat working(at least reads full or close to it when full) it will float. This is rare but can happen.

Good luck, happy fishing!

The avotek book here is kind of our default text book, but I really don't like it. It doesn't do a good job at explaining things, and there's excess stuff.

https://www.amazon.com/gp/aw/d/1933189282/ref=mp_s_a_1_26?ie=UTF8&qid=1485311225&sr=8-26&pi=AC_SX236_SY340_QL65&keywords=avotek

This book is pretty good, but has a LOT of minor errors that can be distracting.

https://www.amazon.com/NCATT-AET-Test-Study-Guide/dp/1484094433

This book is AWESOME! Even though it's not an aviation book, it explains 90% of what's on the AET and it does a really good job at explaining it. You could definitely buy an older addition to save some cash. If you buy this book you will have to use other material for things like FOE, fund. of flight, corrosion, etc.

https://www.amazon.com/gp/aw/d/1111128537/ref=mp_s_a_1_1?ie=UTF8&qid=1485311149&sr=8-1&pi=AC_SX236_SY340_FMwebp_QL65&keywords=introduction+to+electronics&dpPl=1&dpID=51taV6yqLTL&ref=plSrch

Finally, watch these videos on YouTube: https://m.youtube.com/watch?v=SpqwAasxY7U

The guy is a professor at a community college and again, even though it's not aviation related, he explains 90% of what's on the AET incredibly well.

Hope that helps!

Remember 7-11 twists per inch, I think that's IAW AC-43 or this handy book that should be in your toolbox. http://www.amazon.com/Aviation-Mechanic-Handbook-The-Standard/dp/1560278986

Also your middle bolt is "neutral" and is NOT being assisted by the lock/safety wire.

It should look like this: http://image.customclassictrucks.com/f/28178941/1003cct_13_o+how_to_safety_wire+screwheads_double_twist_method.jpg So you have an "S" shape at each bolt. This is so it's always being pulled tight incase a fastener is loosened.

Other people are also right, in that you should be doing the twists counter clockwise at each interval such as: http://firetrucksandequipment.tpub.com/TM-9-254/img/TM-9-254_202_1.jpg The second picture from the top. This pushes the wire into the work so that it doesn't come up over the top of the head of the fastener.

I was also taught not to twist the wire by hand at a 180 degree angle as it might nick it causing stress raiser but as usual YMMV.

Oh yeah, before I forget, bend your tails so you don't cut the next person sticking their hand in doesn't get cut (run your finger over just to make sure). I saw it the other day, on a Cessna Conquest in the engine compartment, it wasn't nice, the guy got cut pretty bad.

Happy to help. This is my 4" block I did at trade school. https://i.imgur.com/GvV19aV.jpg All done by hand...

practice, practice, practice :)

Not quite what I think you're looking for but I'll recommend it anyway.

"To Love An Aluminum Bitch"

An ex-mechanic wrote a book of poems and stories about maintenance. There are some excellent entries in there.

To Love An Aluminum Bitch: Stories & Lyrics of Aviation Maintenance & Adventure https://www.amazon.com/dp/1499635036/ref=cm_sw_r_cp_apa_i_5a04CbTBWAMZC

If you have needle fittings and a little bit of room to work, these hand pumps are great. Got 1 on a whim to try since it was cheap, and I was so impressed I now have one for each type of grease I regularly use.

https://www.amazon.com/Astro-101-Grease-Needle-Nozzle/dp/B000FMK7FG

These would be a good start:

GROL+Radar https://www.amazon.com/dp/0945053606/ref=cm_sw_r_cp_apa_CgirzbRG9608Q

Avionics Training: Systems, Installation, and Troubleshooting https://www.amazon.com/dp/1885544219/ref=cm_sw_r_cp_apa_Giirzb62JVYSC

Plain-English Study Guide for the General Radiotelephone Operator License (GROL) https://www.amazon.com/dp/B00BJ9X8AA/ref=cm_sw_r_cp_apa_jjirzbHP0JBY6

GROL Plus: General Radiotelephone Operator License Plus Radar Endorsement https://www.amazon.com/dp/0945053142/ref=cm_sw_r_cp_apa_Mjirzb020BB3W

Shop around for these or check with libraries.

If he's an older guy. Look at the Bifocal Safety Glasses.

https://www.amazon.com/DPG59-115C-Reinforcer-Rx-Bifocal-Performance-Protective/dp/B000646VF8/ref=pd_bxgy_469_img_3?_encoding=UTF8&pd_rd_i=B000646VF8&pd_rd_r=fbbb5399-ebd1-11e8-b0e1-cb0baae9fd4f&pd_rd_w=kK7sv&pd_rd_wg=xpDG6&pf_rd_i=desktop-dp-sims&pf_rd_m=ATVPDKIKX0DER&pf_rd_p=6725dbd6-9917-451d-beba-16af7874e407&pf_rd_r=R8974SMVVGA3TG0CC050&pf_rd_s=desktop-dp-sims&pf_rd_t=40701&psc=1&refRID=R8974SMVVGA3TG0CC050

Basically reading glasses in a safety frame.

I take a tool bag in the plane and I always put the tool back in the bag and never leave them laying elsewhere. Tool inventory before going in and after leaving will help like /u/ruminatingroy said.

I love these - https://smile.amazon.com/3M-Earmuff-Protectors-Hearing-Protection/dp/B00009LI4K/ref=sr_1_4?s=hi&ie=UTF8&qid=1510080043&sr=1-4&keywords=3m+ear+protection

custom fitted with these -

https://smile.amazon.com/3M-Peltor-Camelback-Sealing-HY80/dp/B00DHVXKVA/ref=sr_1_cc_1?s=aps&ie=UTF8&qid=1510080212&sr=1-1-catcorr&keywords=3m+ear+protection+gel+pads

The Gel pads last for years and years where as the regular ones last only a few months. Plus the gel pads are insanely more comfortable and form fitting giving you better sound protections. The pads are a bit spendy but mine are going on 5 years with no sign of slowing down. I made a custom soft nylon elastic cover to slip over the gels as the gels can get a bit sweaty.

IRWIN makes the best one IMO.

Take a stubby #30 and drill 1/4” in.

Use this on a 1/2” socket and viola.

Use the 1/8” with a #30.

IRWIN HANSON 53227 Hex Head Multi-Spline Screw Extractor Set, 25 Piece https://www.amazon.com/dp/B0002SRG66/ref=cm_sw_r_cp_api_yCuVAb89CXJ6H

Not OP, but it looks like the same thing I use

Not sure if these are any good, I just make my own..

https://www.amazon.com/dp/B0002SRIX2/ref=cm_sw_r_cp_api_NHmMBbFVPVQZ4

https://www.amazon.com/Homak-Industrial-22-Inch-Cantilever-BW00210220/dp/B001CM27N8/ref=sr_1_3?ie=UTF8&qid=1535844986&sr=8-3&keywords=homak

https://www.amazon.com/Army-Universe-Heavy-Military-Mechanics/dp/B000BFNJFW

Those above hold all my tools I need for work. I work for an airline which provides all of the measurement tools, specialty tools or really large stuff. I keep the essentials in the small bag and 95% of the time it has all I need. With most planes, you don't need metric. Only metric I have in my box is a set of metric allen keys ( CRJ map light set screws and Airbus Faucet set screws) and a 13mm socket (some Airbus contactors). Only 1/2 drive I have is one long rachet and a 25/32 deep socket for brake nuts. Most big boxes I see are either half empty, have a dedicated spare parts drawer, or portable locker. I have seen some sheet metal guys with huge boxes and needed every bit of it for stuff.

Bright, LED (higher power lower battery draw). Rechargable. And lastly maybe a plastic body with a grip thats ribbed for those oily inspections. I use a streamlight but its up to you

https://www.amazon.com/gp/aw/d/B0015ZO8VG/ref=mp_s_a_1_1/130-3433638-1209704?ie=UTF8&qid=1521577212&sr=8-1&pi=AC_SX236_SY340_FMwebp_QL65&keywords=streamlight+75813&dpPl=1&dpID=41iTP5r2lML&ref=plSrch

This is the tool.

https://www.amazon.com/Milwaukee-48-32-2100-OFF-SET-Power-Screwdriver/dp/B0000224AW/ref=sr_1_2?ie=UTF8&qid=1474247477&sr=8-2&keywords=milwaukee+angle+driver

Add a electric screwdriver on the end. A 1/4 drive bit socket holder on the other and it starts bolts all day.

Grease pencil?

https://www.amazon.ca/Sharpie-PEEL-OFF-Marker-China-Bullet/dp/B00006IFGI

What about lumocolor?

https://www.amazon.ca/Lumocolor-STAEDTLER-Medium-Permanent-WP4/dp/B0007OEDTI/ref=asc_df_B0007OEDTI/?tag=googlemobshop-20&linkCode=df0&hvadid=292949943083&hvpos=1o3&hvnetw=g&hvrand=7519204589404555918&hvpone=&hvptwo=&hvqmt=&hvdev=m&hvdvcmdl=&hvlocint=&hvlocphy=9000806&hvtargid=pla-318346758646&psc=1

May have to search individually...

https://www.amazon.com/Airframe-Test-Guide-2019-Fast-Track/dp/1619546620/ref=sxbs_sxwds-stvp?keywords=a%26p+study+material&pd_rd_i=1619546620&pd_rd_r=69d0efce-8e21-440c-a081-464ea68999a4&pd_rd_w=lGdic&pd_rd_wg=musLo&pf_rd_p=d006b618-5fac-44e6-850d-a0fdd19f7847&pf_rd_r=7DBE57T3S9QGAY7NTFDP&qid=1564233759&s=gateway&sprefix=a%26p+