Top products from r/finishing

We found 28 product mentions on r/finishing. We ranked the 52 resulting products by number of redditors who mentioned them. Here are the top 20.

1. Understanding Wood Finishing: How to Select and Apply the Right Finish (Fox Chapel Publishing) Practical & Comprehensive with Over 300 Color Photos and 40 Reference Tables & Troubleshooting Guides

Sentiment score: 3

Number of reviews: 3

Latest technical updates on materials and techniques on wood finishingOver 300 color photos that help you distinguish between products, make decisions, and solve problemsMore than 40 must-have reference tables and troubleshooting guides, and much more310 pages softcoverISBN- 978-0875967349

Show Reddit reviews

Show Reddit reviews2. Speedball Super Black India Ink, 1 Pint - 404696

Sentiment score: 0

Number of reviews: 2

The Speedball Super Black India Ink is a free flowing, non-clogging, dye free, ink that offers optimum lightfastness. Non-toxic, 100 percent carbon pigmented ink. Waterproof. Made in the USA. 1 Pint.Fast-drying for your conveniencePermanent design means ink will not fade or grayWaterproof so creatio...

Show Reddit reviews

Show Reddit reviews3. Wood Finishing 101: The Step-by-Step Guide

Sentiment score: 1

Number of reviews: 2

Show Reddit reviews

Show Reddit reviews4. Bloxygen Preserver. Spray, Seal, and Store. 1 can pack.

Sentiment score: 0

Number of reviews: 2

WHAT IS BLOXYGEN?

A powerful and proven formula to save your leftover paints, finishes or food

from getting ruined by oxygen or moisture. Don’t let your expensive supplies go

to waste, use Bloxygen to BLOCK OXYGEN. Simply spray, seal and store.HOW DOES IT WORK?

Bloxygen uses Ultra-Pure Argon Gas. ...

Show Reddit reviews

Show Reddit reviews5. Allway Tools Soft Grip Contour Scraper Set with 6 Blades

Sentiment score: 1

Number of reviews: 1

Item Weight: 8.8 lbCountry of Origin: United StatesBrand name: AllwayToolsItem Dimensions: 1.5"L x 5.75"W x 10.25"H

Show Reddit reviews

Show Reddit reviews6. OXALIC Acid 99.6% 8 oz (Ounces) Deck, Crystals, Metal Cleaning- Rust Removal, Wood Stain Remover and More!

Sentiment score: 0

Number of reviews: 1

OXALIC ACID 99.6% PURE (Dihydrate)Deck, Crystals and Metal CleaningRust Removal, Wood Stain Remover and More!Usage instructions found underneath product picture. If you do not see the instructions you are looking for, simply send us a message and we will respond with the information requested.

Show Reddit reviews

Show Reddit reviews7. Howard Products FW0016 Wood Polish & Conditioner, 16 oz, Orange, 16 Fl Oz

Sentiment score: 0

Number of reviews: 1

Polishes all wood surfaces to a soft luster with a protective coating of Carnauba Wax and BeeswaxIntroduces conditioning oils that “feed” the wood and helps keep it from drying and fadingEnhances the natural beauty and depth of grain in finished and unfinished woodFor use on antiques, dining tab...

Show Reddit reviews

Show Reddit reviews8. Robert Larson 620-1450 Shavehook Set with 3 Blades

Sentiment score: 1

Number of reviews: 1

Comes with tear drop, triangle and combination blades3 easy to change blades with different profilesEasily removes paint from a new project as well as paint from 100 years agoWrench for changing blades included with this setWorks great for scraping dried glue

Show Reddit reviews

Show Reddit reviews9. Rust-Oleum 7778830 High Heat Enamel Spray, 12 oz, Bar-B-Que Black

Sentiment score: 1

Number of reviews: 1

Rust-Oleum Specialty High Heat Spray retains color and finish up to 1200º F.Apply to grills, wood-burning stoves, radiators, engines or other metal itemsProvides rust protection.Durable, corrosion-resistaintDo not use in areas directly exposed to flames (e.g., inside of grills or fireplaces).

Show Reddit reviews

Show Reddit reviews10. Minwax 33250000 Helmsman Spar Urethane Aerosol, 11.5 ounce, Gloss

Sentiment score: 0

Number of reviews: 1

Contains UV blockers to reduce the sun's graying and fading effectsForms a protective barrier against rain and moistureSpecial oils allow the finish to expand and contract with the wood as seasons and temperatures changeIdeal for use on doors, windows, trim, bathroom cabinets, bar tops, kitchen coun...

Show Reddit reviews

Show Reddit reviews11. Minwax 63200444 Helmsman Spar Urethane, quart, Gloss

Sentiment score: 0

Number of reviews: 1

Recommended Uses: furniture, woodwork, molding, cabinets, doors, paneling, accessoriesApplication Tool: natural bristle brushDry Time: 24 hours before normal useCleanup: mineral spirits or paint thinner following manufacturer's safety instructionsContains UV blockers to reduce the sun's graying and ...

Show Reddit reviews

Show Reddit reviews12. CLEARSNAP Pigment Inkpad, Black

Sentiment score: 1

Number of reviews: 1

ColorBox pigment inks are water based and formulated to stamp on absorbent papersThe rich thick inks are fade resistant and do not bleedIdeal for scrapbooking and other projects where longevity is importantTerrific for direct-to-paper and embossing techniquesEasy clean up with waterMade in the USANo...

Show Reddit reviews

Show Reddit reviews13. Minwax 785004444 Paste Finishing Wax, 1-Pound, Natural

Sentiment score: 1

Number of reviews: 1

Minwax Paste Finishing Wax protects and adds hand-rubbed luster to any finished wood surface.It is recommended for furniture, antiques, woodwork, cabinets, doors, paneling and accessories that do not need a hard protective coat of polyurethane.Leaves nice polished look to any finished wood surface

Show Reddit reviews

Show Reddit reviews14. Wagner Spraytech 0417005 HVLP Control Spray Stain Sprayer, Ideal for Decks, Fences, and Latice; Applies thin materials such as stains, sealers, urethanes, varnishes and lacquers

Sentiment score: 1

Number of reviews: 1

HVLP SPRAY GUN: The Control Spray stain sprayer offers control and efficiency when spraying thin materials on small outdoor projects such as patio furniture, small decks, wood décor and moreACHIEVE THE PERFECT FINISH: The Control Finish nozzle sprays a smooth, consistent finish and is designed for ...

Show Reddit reviews

Show Reddit reviews15. Understanding Wood Finishing: How to Select and Apply the Right Finish

Sentiment score: 1

Number of reviews: 1

Used Book in Good Condition

Show Reddit reviews

Show Reddit reviews16. Rust-Oleum Zinsser 408 Bulls Eye Clear Shellac Spray 12 oz

Sentiment score: 0

Number of reviews: 1

This product adds a great valueAll-Natural, non-toxic, and easy to useClassic finish for wood trim, paneling and furniture

Show Reddit reviews

Show Reddit reviews17. SC Johnson Paste Wax- 16 oz (1lb)

Sentiment score: 1

Number of reviews: 1

Flash point: 31.00 degrees_celsius

Show Reddit reviews

Show Reddit reviews18. Foolproof Wood Finishing, Revised Edition: Learn How to Finish or Refinish Wood Projects with Stain, Glaze, Milk Paint, Top Coats, and More (Fox Chapel Publishing)

Sentiment score: 1

Number of reviews: 1

Show Reddit reviews

Show Reddit reviews

First off, I always recommend "Understanding Wood Finishing" by Bob Flexner. It's pretty simple straightforward advice and it's only $15. https://www.amazon.com/Understanding-Wood-Finishing-Comprehensive-Troubleshooting/dp/1565235665

Here's what he recommends:

>WALNUT

>

>Walnut is America's supreme native furniture hardwood. It is a hard, durable wood with a beautiful figure and rich, dark coloring. It has a smooth, medium-porous texture that accepts all stains evenly, and it finishes nicely with any finish. The coloring of air-dried walnut heartwood is a warm, rust red. The coloring of kiln-dried heartwood, which is commonly steamed to reduce heartwood and sapwood color variations, has a colder charcoal gray cast. As steamed walnut ages, the gray warms to a tan with a slight reddish tint. The reddish tint in aged walnut makes it difficult to distinguish from mahogany in old furniture.

>

>There are two finishing problems presented by walnut: the color contrast between the dark heartwood and the almost-white sapwood, and the coolness of steamed walnut.

>

>There are four ways to overcome the color contrast between heartwood and sapwood:

>

>• Cut off all the sapwood so you're using only heartwood.

>

>• Arrange your boards so you use the color differences to decorative advantage.

>

>• Bleach the wood to a uniform off-white color and then stain it back to whatever color you want. (See "Bleaching Wood" on page 80.)

>

>• Stain the sapwood to the color of the heartwood with a dye stain, and then stain the whole to the color you want.

>

>Woodworkers making one-of-a-kind furniture usually choose one of the first two methods: They cut away the sapwood or they use it decoratively. Bleaching walnut was common in factories when blonde furniture was popular in the 1950s. Today furniture factories use stains to blend sapwood and heartwood.

>

>You can warm the tone of walnut by staining it or by putting color in the finish. You can use any type of stain, though a gel stain will not bring out the full richness of the figure. Most finishes contain a natural amber tint that warms the wood a little. Orange shellac contains the most color, and it is often used on walnut for this reason, though it's not a durable finish for tabletops. Water-based finishes are totally devoid of color, so there is more reason to use a stain under water base than under any other finish.

>

>Personally, I like just about any finish on walnut. I've used oil/varnish blend, wiping varnish, and film finishes. For objects other than tabletops, my favorite finish is orange shellac because of the warmth it adds to walnut (Photo 17-12 on page 268). When using other finishes, I often add warmth by staining the wood (a dark rust, commonly sold as American walnut) or adding dye to the finish (again, dark rust) and toning the wood.

​

The only thing I'll add is "test, test, test". Don't try your ideas out on the final chest. Use test pieces of walnut to see how you like the results.

On my end, I've learned to hate tung oil. It's pricey, the real stuff takes a month to dry, and if it's drying faster than that... it was probably linseed oil I just overpaid for. :-/

Linseed oil has a great feel to it, but works best for dark woods or over dark stains; it'll yellow more than true tung oil over time.

The problem I see with your original plan is that the stain will mostly seal the wood, so the oil either won't soak in to give any protection... or the oil will re-wet the stain and pull up the color, which isn't a win. Oil works best on it's own, or maybe mixed with a dye, but

Bob Flexner's books are also fantastic here. If you have time to spend, this is used as a textbook for classes on wood finishing.

https://www.amazon.com/Understanding-Wood-Finishing-Select-Finish/dp/1565235665

So going all the way back?

I've refinished more than a few 100 year old doors. If you want bare wood and stain it'll take time and care, if you're going to repaint it'll take sightly less time and care. Depending on condition just a simple paint scraper can do the trick nicely. If there's a lot of detail you'll want a contour scraper like this

https://www.amazon.com/Allway-Tools-Contour-Scraper-Blades/dp/B000BQMZ9C/ref=mp_s_a_1_14?keywords=paint+scrapers+for+wood&qid=1566143184&s=gateway&sprefix=paint+scraper&sr=8-14

If it doesn't scrape easily my next move is a heat gun and a putty knife. You'll still want the contour scraper if there's a lot of detail.

I've also used one of the electric paint strippers called "the silent paint remover". IMO it covers more ground at once but you can accomplish the same thing with a simple heat gun. Depends what you want to spend I guess.

I've had good luck with these methods on many doors and I've never had to resort to chemicals, at least on doors and windows I've done. As another poster said, chemicals will just get everywhere if you're not using sawbucks.

Arm-R-Seal is an oil-based urethane. You wouldn't want to use a polyurethane over it; you're essentially finished. 3 coats of that stuff should be fine, adding any more is kind of unnecessary. The only time you add more layers of finish is when you're working with tung oil, shellac, or high-end finishes like conversion poly/lacquer.

Your best bet would be to possibly shine this up with some Johnsons Paste Wax that you can buy at Lowes or Home Depot if you don't use Amazon. Wait a week or 2 to let the finish gas off, and dry up a bit more, and use this paste wax every 6 months to a year. It's been around forever, and works really well.

Edit - If you haven't, make sure you've sealed the bottom of the butcher's block as well. You don't want one side sealed, and the other unsealed; granted, this type of butcher's block with multiple pieces glued together will not move as much as a panel glue up would, but it's still a good practice to always finish the bottom as well.

This is a good one. Lots of recipes and good explanations. I also like Teri's promotion of step boards so you can see the progression of different steps on your own https://www.amazon.com/Foolproof-Wood-Finishing-Revised-Publishing/dp/1565238524/ref=dp_ob_title_bk

Unfortunately, repairing porcelain enamel surfaces isn't a DIY job. There are some products for bathtubs and there are high temperature enamel paints, but those aren't porcelain enamel coatings. There are companies that can refinish the item for you, like this one, http://www.ipe-porcelain.com/, no idea if they are any good though.

If this for an oven, and the part doesn't actually touch food, I'd contact Rustoleum, they make high temp enamel paints for grills, I'd imagine an oven a similar enough to be okay, though you might need bake in the finish before cooking food in it. https://www.amazon.com/dp/B0010O0C94/ref=cm_sw_r_cp_awdb_t1_x0J3BbHXPYC45

Do you have any specific Flexnor book in mind, are they all the same, or should someone read them all:

...Are the Flexner books mostly about brushing/rubbing on finishes? Any recommendations for good books on spraying a finish for a beginner? Like explaining the various setups (HVLP, etc.) and the finishes available?

I'd need to see the piece in person to decide if it was a wood veneer or just a picture of wood before I advised doing anything more drastic than polishing the existing surface.

That said, pick yourself up a tin of this or this or any other clear paste wax and rub it into the damage well before doing the whole box. Hopefully that makes it acceptable.

The chemical paint removers might actually be safer too. Old woodwork is likely to have lead paint on it. Sanding will turn it into dust that can be inhaled and will settle throughout the flat.

To get the best results with stripper buy a shavehook set like this:

https://www.amazon.com/Robert-Larson-620-1450-Shavehook-Blades/dp/B0012XP6ZS/ref=sr_1_2?ie=UTF8&qid=1468860049&sr=8-2&keywords=shavehook+set

There are cheaper ones available but this is a high quality tool.

No. It would just spatter little droplets on the wood and make a mess. A spray bottle doesn't atomize the finish. A spray gun does if the pressure is high enough. A spray gun shouldn't be a pain... can your compressor handle the CFM requirements of the gun? Check out turbine HVLP systems. It is the same gravity fed spray gun you would use with the compressor, but with a turbine to continually make air instead. It will set you back some $$$, but they are great. You don't need a compressor. Those airless sprayers are really more for thick house paint, since they don't atomize the finish. Atomizing the finish is a must for getting it to flow out nicely and not splatter and orangepeel.

sure thing, here is a picture of the print itself. This is the ink that was used. The print is on a lid to a box as well

One more vote for india ink. I've used it on red oak before and it turns completely jet black with the texture of the grain still visible but without any color variation.

If you want solid black no stain even comes close to india ink. It is also cheap and doesn't smell toxic. This is the one I used: www.amazon.com/gp/product/B003IGK1OI/ref=oh_aui_search_detailpage?ie=UTF8&psc=1

I would get some india ink and try it out on a few scrap pieces of different woods. I suspect you'll find that you don't need to use a wood as expensive as walnut to get the result you are looking for - any inexpensive hardwood like oak should work just fine.

I recommend reading Flexner's Wood Finishing 101 first. It's the simplified version of his popular "Understanding Wood Finishing" book. I read it after a few woodworking projects and it really made me realize what kind of mistakes I had made in the past.

Would India ink work?

Dark Walnut comes close. BLO doesn't "protect". For outdoor protection use some Polyurethane made for the outdoors, such as:

Minwax 33250000 Helmsman Spar Urethane Aerosol, 11.5 ounce, Gloss https://www.amazon.com/dp/B000Z8DGJE/ref=cm_sw_r_cp_api_9ScUzbY3QPPYS

https://www.amazon.com/OXALIC-Crystals-Cleaning-Removal-Remover/dp/B0793F89NT/

So then, do your gel stain, let that dry for a day. Get a can of shellac and put on a coat of that. Let it dry for an hour or so, then 3-4 coats of a wipe on poly and you should be set

I just tried using Bloxygen Preserver.

https://www.amazon.com/gp/product/B0002088O8/ref=ppx_yo_dt_b_asin_title_o09_s00?ie=UTF8&psc=1

Flexner's book is the go-to that I know of - https://www.amazon.com/Understanding-Wood-Finishing-Comprehensive-Troubleshooting/dp/1565235665

It's a brand name for a spray can sold to preserve finishes by blocking oxygen. It's just a can of Argon.

https://www.amazon.com/Bloxygen-Grams-Finish-Preserver-Spray/dp/B0002088O8

Howard Products FW0016 Feed-N-Wax Wood Polish and Conditioner, Beeswax &, 16 oz, orange, 16 Fl Oz https://www.amazon.com/dp/B001BKQYGW/ref=cm_sw_r_cp_api_i_7lT0DbCBGF871

Used this Feed-N-Wax on a table I received from my parents. It was disgusting and my wife and I hid the top from view with table clothes for a while. Bought this on a whim and years of rings and marks on it were taken off on a single wipe.

If I remember correctly from https://www.amazon.com/Great-Book-Woodworking-Tips-Photo-Illustrated/dp/1565235967/ref=sr_1_7?ie=UTF8&qid=1523536711&sr=8-7&keywords=Wood+working+book

Lay sand paper on the trim rough side out, then rub the sort of foam you’d stick fake plants into on it. Now you have somethingin the shape of the trim. Use sand paper, rough side toward the wood this time with the foam as a sanding block.

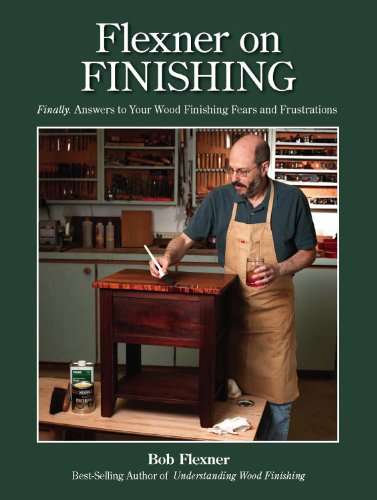

Read.. Flexner on Finishing: Finally - Answers to Your Wood Finishing Fears & Frustrations by Bob Flexner

https://www.amazon.com/Flexner-Finishing-Finally-Answers-Frustrations/dp/144030887X/ref=sr_1_1?ie=UTF8&qid=1500064483&sr=8-1&keywords=Flexner+on+Finishing%3A

Your plan sounds wrong to me. I don't like to mix chemistries

Behlens rock hard is varnish. The various different wipe-on products are thinned varnish. Polyurethane is varnish with a slightly different chemistry than alkyd. Shellac is a dried and powdered bug parts in alcohol

If I was going for a varnish finish, I would start with varnish, let it dry well, sand and apply another coat, and repeat until you have the build you want

And yeah, marketoids lie all the time. So-called "Tung Oil" finish is most often varnish, thinned with mineral spirits