(Part 2) Best manual sanding products according to redditors

We found 84 Reddit comments discussing the best manual sanding products. We ranked the 31 resulting products by number of redditors who mentioned them. Here are the products ranked 21-40. You can also go back to the previous section.

For the nut slots get some abrasive cord in appropriate diameters for the slots you'll be working on.

You want to be really gentle and go slow as you're removing material and don't want to go too far but it's really useful for polishing/smoothing out those slots so strings don't bind for better overall tuning stability.

I was probably one of the people encouraging you to do this in the first place - everyone should know how to take a screwdriver to their electric guitar and move the setup points around. As long as you pay attention to what you're doing there's very little risk of damaging anything.

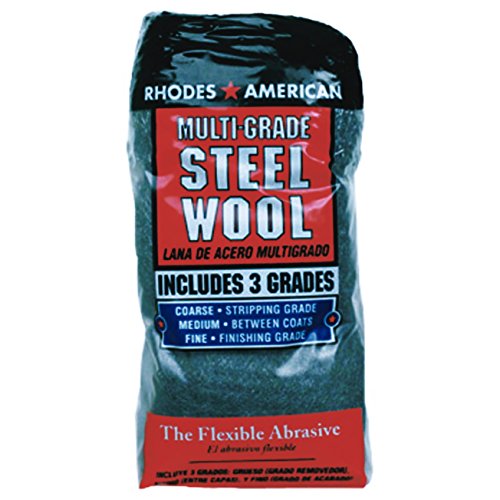

Find the holes. All of the holes. Then put this into and or around the holes http://www.amazon.com/Homax-Group-Steel-Extra-Coarse/dp/B0000DI7ZC/ref=sr_1_4?ie=UTF8&qid=1463966858&sr=8-4&keywords=steel+wool and cover the steel wool with some of this. http://www.amazon.com/31084-Concrete-Interior-Exterior-1-Quart/dp/B000BOAD3E/ref=sr_1_2?ie=UTF8&qid=1463967006&sr=8-2&keywords=cement+patch+quart Smash a little more of the cement product into the steel wool. You can use a 1 inch putty or butter knife. Let dry and viola, reinforced cement with steel wool at the nose. No mice in. Also seals the draft.

depending on how rough it feels I would suggest starting with an 80g or 100g and then finishing with 120g and 220g. You can skip the first one if it is not super rough. Get one of those sanding sponges with the different angles on them. That will be easier on you hand than just sand paper. Becasue of the shape you'll want something that you can wipe or spray on. Use 4-5 thin coats. The easiest/cheapest option would be a wipe on poly or even better an Aerosol Spar Urethane. EDIT Also, sand lightly in between coats with 220 or higher. This helps the next coat stick.

You might also consider trying to fix a few of those larger cracks by filling them in with a two part epoxy

Good luck! It will be a nice surprise for her when she returns.

It looks like this: https://www.amazon.com/Norton-Screen-Bak-Abrasive-Backing-Waterproof/dp/B001HWOE6Q

I searched for "wide mesh sanding screen." I think the only issue is determining the grit. Also, you might have to buy one million yards of the stuff.

Are these what you are recommending? Thank you so much for your help.

https://www.amazon.com/Scotch-Brite-Abrasive-General-Purpose-Aluminum/dp/B001S8HF9W/ref=sr_1_2?ie=UTF8&qid=1469192797&sr=8-2&keywords=Scotch+brite+pads+maroon

Assuming the burr is on the hole through the tuner peg, you’ll want abrasive cord to deburr it.

If the string is breaking at the tuner, the string retainer probably doesn’t have anything to do with it. For reference, the string retainer should be set just low enough that the strings are in contact with the nut surface over the entire nut. If it’s set too high and the strings rise above the nut on the headstock side, clamping the nut down will cause the strings to go sharp.

Considering the amount of corrosion visible and that it has no specific marker's mark I think if it were put up for auction on Ebay then you would be lucky to get $50 USD. If it was completely cleaned up then the price would probably double.

If you feel confident that you could do it without damaging the blade or scales then I would recommend trying to remove the corrosion from the blade. You could use steel wool and a wire bristle brush to clean off the corrosion. Then oil the blade with WD-40 or mineral oil to prevent any further corrosion. This will at least help preserve it for future generations of your family. Hopefully it is something they will keep and treasure for many decades!

3M have other sanding sponges in finer grits available. ultrafine 800-1000 grit, and microfine 1200-1500. You're just using superfine, which is a 300-600 grit. What you want to do is use all three in succession to make the scratches less visible, so when you get on to the highest grit you are buffing the plastic back to mostly what it looked like before sanding.

https://www.amazon.com/3M-Ultrafine-Softback-Sanding-Sponge/dp/B0035R284G

https://www.amazon.com/3M-02600-Microfine-Softback-Sanding/dp/B001KVXTXI

That's wholes boxes for sale, just linking to show them, but you can probably search around for individual pieces for sale on Amazon or Ebay to save buying a whole box.

Sorry, no before/afters! I was remove really tough water stains. I had tried some other techniques, but a friend of mine recommended I use 00 and Glass Cook Top Cleaner. I accidentally ordered 0000, but found out it was more fine so I figured I was safe. Here's what I used:

http://www.amazon.com/Red-Devil-0310-Steel-Super/dp/B001SBJFVA/ref=sr_1_3?ie=UTF8&qid=1377139761&sr=8-3&keywords=0000+steel+wool

http://www.amazon.com/Weiman-Glass-Heavy-Cleaner-Polish/dp/B004YF3ZU4/ref=sr_1_2?ie=UTF8&qid=1377139773&sr=8-2&keywords=glass+stovetop+cleaner

It took me awhile to get all of the hard water stains (2009 Honda Civic), but it was soooooo worth it!

Edit: Also, I will say I have noticed there are noticeably less (or none at all) superficial scratches compared to before.

try this, it's what my local wood shop recommended: http://www.amazon.com/gp/product/B000L6IXLG/ref=oh_details_o07_s00_i00?ie=UTF8&psc=1