(Part 2) Best bench vises according to redditors

We found 216 Reddit comments discussing the best bench vises. We ranked the 64 resulting products by number of redditors who mentioned them. Here are the products ranked 21-40. You can also go back to the previous section.

I'll just leave this here because it's bad-ass.

Id get him a stop loc. I use one for lathe work all the time when I'm trying to pull a consistent length of stock through the chuck. It's accurate to about +/- .007 When you use it right. Usually i set my zero to about .01" closer to the chuck than where the end of the stock ends up and take a .015" face cut at zero to eliminate the error from the stop loc. Can also be used on a mill vise in some situations where a normal stop isn't that helpful.

You can enhance the function by drilling a hole in the center of the red stop and pressing a magnet into it. That way the stop loc holds on to your stock a little better if you do any steel work. Won't help with aluminum, but if you press the magnet in flush it won't hurt either.

https://www.amazon.com/Stop-Loc-Lathe-Stop-Milling-Width/dp/B00H9P0HK2

Edit: for milling work Id nab one of these:

http://www.ajaxtoolsupply.com/mivistfor56i.html?cmp=googleproducts&kw=mivistfor56i&gclid=Cj0KCQjw24nNBRChARIsALldLD2zfENShZz0Q2vfyO4HiCJjmxtOccJ1EPbmsCsQsAemSWcQJr2GVQUaAi1HEALw_wcB

Save yourself some money dude. You can easily create these for under $90 for two. Get these or similar drill vices: https://www.amazon.ca/gp/product/B01MCS9QWI/ref=oh_aui_detailpage_o00_s00?ie=UTF8&psc=1

Then go to your hardware store and pick up 90 degree angle ties like these: https://www.homedepot.ca/en/home/p.6-inch-x-6-inch-x-1-12-inch-12-gauge-90-degree-angle-tie.1000170469.html

Then bolt them to the vice grips via the screwing areas, then slap on a plywood to fit the throttle and stick. It'll be height adjustable too.

I got the idea from this dude (bless his/her heart) https://www.reddit.com/r/hotas/comments/2palix/cheap_diy_hotas_mount_i_just_made_xpost_from/

I found a shortcut to this either on tv or reddit comment I don't really remember. This will ruin the book so sell the digital copy accordingly. You also need a scanner that works on a feed system aka ADF like a fax machine (rather than a slow flatbed ) but beware of low end ones which are more trouble than they are worth. This does 40PPM which means 1000 page book in under 30 minutes. Put the book on a table clamp and use an angle grinder to grind off the binding don't forget to get goggles to keep paper out of your eyes. Take the covers off and feed the pages. Looking at the price of the materials startup at 500 is costly which could be cut down by buying a cheaper scanner to 300 or finding someone who already owns one which would cut the cost down to <50$. Of course if you already have all the materials what the hell are you waiting for. If not you could or could not use the amazon links provided to do this.

I'm headed back home (NC) for a week long vacation. Are there any cerakote applicators in or near Wake County that won't charge an arm and a leg to coat a Mossberg 500 receiver, mag tube, and barrel?

In Newyorkistan I managed to secure a stripped lower at a gunshow! This is significant because none LGS will transfer them now. Any ways, I also want to build my own upper as it seems straightforward enough. I have most of the tools I'll need lines up but I want to make sure I get a good enough vise. Is low profile good enough when torquing the barrel nut?

Is it common to want to buy 2-3 more stripped lowers after your first one?

Look into a PanaVise 209. The base is 3-3/8" wide, and it can extend up to 7-1/2" tall

I knew this bench would be sort of "baby". That is, I knew it would be just a benchtop (so common holdfasts are out), it would be cheaply and quickly made, and someday when my shop is not in my kitchen I would build a "real" bench.

I wanted some kind of hold-down clamps, but lacking the space below the deck, they'd have to attach somehow to the deck itself. At the time I was enamored with aluminum extrusion, especially its use in a knockdown turntable stand I was building.

As for the brand, I think I simply stumbled upon it through Amazon.

When I'm ready to invest in and build a bigger, heavier, less-flat-packable bench I want it to have Jorgensen vises & dogs: Jorgensen 41012 vise, Jorgensen 40709 vise, Jorgensen bench dog

Honestly, just buy a vice and a block. If you're in a place where you won't have a good bench to mount it, get a clamp-on vice and put it on a heavy table or desk.

If you're planning on doing much AR work at home, it really is the best way to do it. Bite the bullet, it makes things much easier.

You'll need a bench with a vise so I'd look for tools that help me build one. There are hundreds of bench designs around but IMO the most important things are that it's heavy and rigid and that the legs are flush with the front edge of the top. If you're serious about it you could ask for one of the books on bench design. I'm only familiar with Chris Schwarz's blue book, but I can recommend it.

For a vise, a standard metal quick-release like this would be fine. You could also go with this style which is easier to mount flush to the bench's edge.

Last February I bought the Yost 10 inch vice for $58 from Amazon with prime shipping, but I see that it's gone up and now is just $10 less than the Shop Fox. Still, it's a great value too, install instructions sucked but it's rugged and works smoothly.

eh these ones i linked a few minutes ago were 4 inch not 6 inch like HF has. I believe they do have the 6 inch.. but more expensive than HF. HF shipping is 6.99 though. Pretty good deal if they dont have it in store.

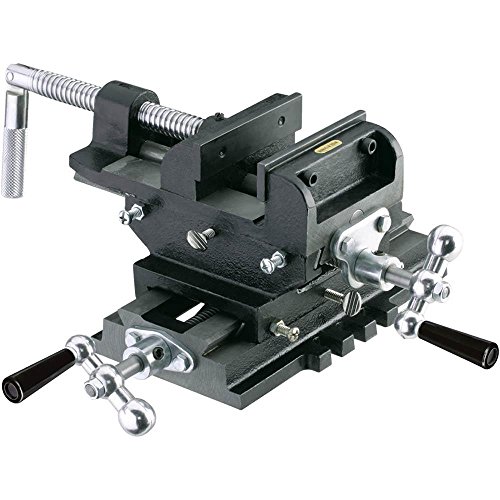

http://www.amazon.com/Grizzly-G1064-Cross-Sliding-Vise/dp/B0000DD0C7/ref=sr_1_4?s=hi&amp;ie=UTF8&amp;qid=1407771604&amp;sr=1-4&amp;keywords=cross+slide+vise

http://www.amazon.com/Woodstock-D4082-4-Inch-Cross-Sliding-Vise/dp/B005W16WT0/ref=sr_1_2?s=hi&amp;ie=UTF8&amp;qid=1407771604&amp;sr=1-2&amp;keywords=cross+slide+vise

The ideal tools would be a CNC mill, but for cheap DIY I used the following.

https://www.amazon.com/dp/B005UKGLAS 10" drill press

https://www.amazon.com/gp/product/B077QMBVTB X-Y vice

That plus a few drill bits, end mill bit, and some hand files will have you milling out 80% lowers for around ~$200. Never milled my own upper so I have no idea what that entails. I recommend starting with poly lowers for your first couple, they are more forgiving and less likely to break any off your tools if you mess up.

&#x200B;

edit: if you want something you can drop a lower into and walk away, check out this https://www.ghostguns.com/home/173-ghost-gunner-cnc-version-2.html

Ever considered a small suction base vise? If you have a flat & clean enough surface on your tank, they work well and are pretty versatile on angles. I don't use mine for that but I use it for soldering all the time, and have thrown it on my tank to hold tools or brake fluid reservoirs and it's never fallen off.

I got this one:

https://www.amazon.co.uk/Hi-Spec-Swiveling-Mechanism-Electronics-Multi-Angle/dp/B01N96LEDB

It’s cheap and does the job well :)

https://www.amazon.com/MaxWorks-80775-Articulated-Vacuum-Bench/dp/B0792N41Q8

Ended up going with this vice for now, anyone else used it?

https://www.amazon.com/Drill-Press-Compound-Cross-Slide/dp/B01LDY6EAG I suppose I could use one of these in coordination with a drill press?

Very nice. There was a similar Wilton on CL here for a long time. I just looked now and it is gone, hopefully unlisted/expired rather than sold. But it had a damaged jaw and one of the pipe jaws was missing entirely. $300, if you can believe it. That is pretty representative of the CL vise market here. Lots of low-info sellers trying to get too much for old junk. Actually, some of it might be nice, but you can't tell from the dark pics of poorly painted "restorations".

I got impatient and got a pretty good deal on this Yost, but not nearly the sort of steal that you did. I am quite happy with it so far. Of course, I would immediately jump on the sort of deal you got. Then I would have to decide if I wanted to keep it or if I wanted to quadruple my money (or more).

I use this one. Dont use a pipe extension to tighten and it'll be just fine (It is a lighter duty vise).

Rubber and aluminum vise caps (4.5") to go with it.

http://www.amazon.com/HHIP-3900-2104-Pro-Series-Positive-Milling/dp/B00E0ND9N8?ie=UTF8&amp;psc=1&amp;redirect=true&amp;ref_=oh_aui_search_detailpage

I have that vise, and it's really not bad at all.

Swivel vise

https://www.amazon.com/Yost-Vises-250-Clamp-Bench/dp/B002PCMKGI

Nope no drilling, it's got a clamp. I'll normally have to retighten it a couple times when using it, but it gets the job done alright.

Yeah I made sure to go all out on the casters. They are rated for 500lb a piece. Nice having the larger surface area when moving it.

The piping for the shopvac is the next priority. I have an idea where I want to run so it won't impact the storage but also not have many bends adding to the run length.

Question to anyone, do you run a chip bucket before the shopvac? I am debating having it all run through a chip basket first to get the big junk. The planer I am going to run a completely separate line.

I have a vice that will be mounted off the side. Something similar to this.

https://www.amazon.ca/6-1-Woodworking-Vise-Bench-Dog/dp/B002I2KFMG/ref=mp_s_a_1_1?keywords=vice&amp;pd_rd_r=a9666810-31b6-4fa7-adbe-1989e615c013&amp;pd_rd_w=KLaCe&amp;pd_rd_wg=9ktKY&amp;pf_rd_p=4cae2a3b-d298-4883-930a-9e8104e24e48&amp;pf_rd_r=2YK6R807EY4SA76SG26N&amp;qid=1571110337&amp;s=kitchen&amp;sr=1-1

Right now I have another vice that is on a workbench in the back room, left there from the previous owner of the house. It's ok for when ya really need one.

Cheers

Trying to stick with Amazon...

General: do not get no-name generic Chinese tools. These will fail in no time.

Cheap tools are the more expensive. Partly through the damage they cause and the time they waste, and partly because you're going to throw them away and get the good ones anyway eventually.

Get some good screwdrivers. Yellow plastic handles with rubber grips. Stanley used to be good, but apparently not any more. Most screwdriver sets contain more screwdrivers than you need. Klein seems to be the brand to get now, but they're quite expensive. I'm not a fan of multi-bit drivers, but this one looks pretty good and you can't beat the price: http://www.amazon.com/Klein-Tools-32477-Screwdriver-Driver/dp/B0002RI5EY/

This looks like a superb set, but at $60 it really eats into your budget: http://www.amazon.com/Klein-Tools-85078-Cushion-Grip-Screwdriver/dp/B000ABADXI/

Saws: Get the Japanese pull saws. I like my Ryoba. There's a plastic-handled version at http://www.amazon.com/Shark-Corp-10-2440-Fine-Cut/dp/B0000224U3/ that's pretty good. The one that abnormal_human linked to is an excellent choice. I would go with that. In fact, it's going on my wish list.

Power tools: You won't regret getting a 14 or 18-volt DeWalt electric drill. There are a couple of 18-volt tools on sale at Amazon right now. Don't argue; just get one. Don't forget drill bits. I like the cobalt, but Titanium is good.

I wouldn't bother with any other power tools; the good ones cost money and the cheap ones will only bring you grief.

Do this: buy a cheap but complete set of HSS bits. As they wear out, replace them one by one with cobalt. I got mine at Costco. I didn't see any on Amazon.

Get a tape measure. I wouldn't spend $25 if money is an object. This is probably the single-most important purchase.

Get as many clamps as you can afford. Not metal C-clamps; those are for metal working. Irwin quick-grip or clone and Jorgensen or Bessey bar clamps are your best value here.

Chisels: I'm not sure you need these for a minimalist wood shop, but if you get them, get a 1/4" and 1/2" chisel. That's all you really need. abnormal_human linked to a pretty good sharpening stone. Japanese chisels are the best, but they'll bust your budget, and until you learn to sharpen them well, they'll be a waste of money. Just get a cheap Stanley or DeWalt set. Expensive chisels will come pre-honed. Cheap ones you should hone for best results. You need to learn to hone them anyway.

Don't spend $50 on tweezers. But get a good pair at your local drug store and get a pair with the longest, sharpest, pointiest working end you can find. And a magnifying glass so you can see the splinters.

Get a 12" combination square. Don't get an expensive one, but don't get a no-name tool either. Some of them have a built-in level which you will never use.

Get a large carpenter's square. They're cheap.

I wouldn't get a card scraper. They're nice, but hard to sharpen and you really need a burnisher ($22) to do it properly.

Consider buying the hardware to build a good workbench. And by that, I mean a good bench vise. A very good one can run you around $200, but this one looks pretty good for $21: http://www.amazon.com/Olympia-Tools-38-736-Hobby-WoodworkerS/dp/B002I2KFMG/ and $66 will get you this very decent one: http://www.amazon.com/Woodstock-D4026-Cabinet-Makers-Vise/dp/B005W16LVE/

ETA: If you still have budget left for power tools, a random orbital sander is nice and not too expensive. I'm using a borrowed Ryobi and I have had zero issues with it. (I'm not normally a fan of Ryobi, but this one is pretty good. http://www.amazon.com/Factory-Reconditioned-Ryobi-ZRRS290-5-Inch-Random/dp/B001HTPSKK/

Finally: a cheap Wixley or iGuaging digital caliper is a good investment. Within a week of buying one, I was wondering how I'd survived so long without it.

Those three solder suckers are basically the same, and all good: metal tube that doesn't scar from molten solder, and a spring actuator latch you can work with one hand. Those all have a standard size tip (and standard size ramrod for clearing it after use); see if you can also find one that takes a smaller tip (the print on mine are long since abraded away, sorry), because there'll be times when that more precise tool is better. Also, have a spool of Solder Wick on hand (and get some practice with it beforehand so you know when it's more appropriate).

The strippers... That looks enough like the Ideal tool I use, but also get one that goes up to 30-gauge.

Get a DMM.

Iron: I'm still using the Weller WTCPL I bought in '74 or '75, with a coupla parts worn out and replaced along the way, proof that a good soldering station will last you for years. I swap tips depending on the workpiece; make sure that model you buy makes that easy, and that the offered tips go up to at least 1/8" width (for soldering transformer lugs and ground planes).

I'm not fond of the gator clip style of 'helping hands'. Working styles vary, but I think you'll get more productive use out of a mini bench vise like this or this, or, better, something built with steel rather than aluminum. Mine is 1-1/4" wide and steel, and it has that half-finished "made in Asia" look but it works. The important point is that it clamps to the edge of the workbench so it's immovable even when you're hacksawing a piece of circuitboard or pounding a bent piece of brass flat for a ground lug.