(Part 3) Best abrasive & finishing products according to redditors

We found 392 Reddit comments discussing the best abrasive & finishing products. We ranked the 187 resulting products by number of redditors who mentioned them. Here are the products ranked 41-60. You can also go back to the previous section.

Make sure you’re using a cut-off wheel. It’s about the thickness of a DVD disk. Then position the blade beneath the head of the bolt, and cut it off. The goal is to be able to pull the bolt out from the bottom. Top if you’re lucky.

Link to cut off wheel for angle grinder

4 1/2" Cut Off Wheels for Cutting All Ferrous Metals and Stainless Steel 10Pcs https://www.amazon.com/dp/B078GN6DR6/ref=cm_sw_r_cp_api_i_Lg6sDbPKP48TB

A mop or bristle sander is helpful to get the fuzzies out without impacting the carve.

I use these for machined carves -

https://www.amazon.com/Abrasive-Nylon-Woodwork-Polish-Grinder/dp/B0787ZPHKN/ref=sxts_sxwds-bia

I think it was u/purplepiratecrab that asked to know how the tumbling was going. Well, I think I’ve had good results with my first couple of test piece. One is an Axiom Tetra Bead-blasted Stainless Steel.

The spinner has good weight and balance, but I never cared for the bead-blasted finish. It was too rough and all the points and corners were far too “hot” for my taste. As it was my first foray into tumbling I threw all manner of media at it - Grits, SS Shot, Ceramic, Dish Soap, Baking Soda, and Polishes. There is plenty of advise online for tumbling stones, but surprisingly little instruction on metal (jewelry) tumbling. But I consumed what I could find.

I am using a Harbor Freight Chicago single-drum tumbler. I had gathered that the rubberized drum that comes with the tumbler was not ideal for metals like Stainless Steel (turns them black). So, following after a YouTube video, I assembled my own PVC drum. You do need to add baffles inside the drum. Otherwise, everything simply clumps at the bottom and nothing actually tumbles.

https://share.icloud.com/photos/08Yoc5CX4Il2v081JWrErA94A

https://share.icloud.com/photos/0NUNMe7gag16MZl6OG4FaAgzA

I ordered 1 lbs of Stainless Steel shot and 1 lbs of Small Ceramic Media from Amazon. Harbor Freight has Grit / Polish packs as well. Add water and a drop of Dawn dish soap and you’re ready to go.

https://www.amazon.com/dp/B017WQV6UM/ref=cm_sw_r_sms_c_api_i_HZNpDbEB0T5MA

https://www.amazon.com/dp/B07DY7PSBT/ref=cm_sw_r_sms_c_api_i_cYNpDbC80MBHD

https://www.amazon.com/Thumlers-Tumbler-Polisher-Accessories-Prepolish/dp/B000BUW610

While rock tumbling can takes weeks, metal tumbling over hours or days can get good results. If you simply want to knock off “hot” spots, 6 hours with some SS shot works great. I did that with a Brass Spinetic Micro-X which had super “hot” corners on it. Quite comfortable after that.

https://share.icloud.com/photos/0EthP9bf8BLlK-E1OPfdYFYoA

The last round with the Tetra involved 7 hours with Ceramic Media, 6 hours with Shot and Pre-Polish, overnight with Shot and Polish, and then 6 hours with Shot and Baking Soda. Even without the rubberized drum you are going to get a lot of black dust in the polishing stage so the soda really cleans that off of SS and cleans your Shot at the same time (otherwise you’re left with gray dull shot at the end).

The results are very satisfactory for a piece with a lot of edges like the Tetra. The photos above don’t really do it justice, but what I ended up with was something very close to UQH’s Fine Stone-Washed effect - smooth slightly soapy feel. Much better than the rough, hot finish it had before. I then sanded and polished the flats on both sides for a nice contrast. The Vortex Buttons from UQHs really makes this a unique piece - far more fondalable than it had been originally.

You do need a bit of patience and willingness to experiment with various combinations to appreciate the varying results. I want to try adding plastic media for cushioning. And If you want truly mirror polished pieces then further sanding and a polishing wheel would be necessary. Definitely more experimentation and learning is in my future. Hope this has been informative. Cheers!

I'd guess it was used as a dispenser for sandpaper or other materials that came on a roll https://www.amazon.com/Sandpaper-Dispenser-Furniture-Restoration-Automotive/dp/B07457VPWY

I believe those nuts are crimped, and the threads are probably rusted and fused solid. You're in for a fight.

I got a Milwaukee 2767-20 M18 1/2-Inch Impact Wrench with Friction Ring specifically for dealing with problems like this. It is amazing and has saved tons of time. But an impact wrench might not work if the torx head is damaged enough.

Skip the torch. If you can't get an impact on it, your best bet is to cut the bolt off. You have three options: Cut the nut-side off and punch the bolt out through the bushing and axle mount. This won't work if the bolt has rusted solid to the steel insert in the bushing (it probably has). Option two is cut through the bushing directly next to the mount, and punch the bolt-head out. The last option is to cut the torx head flush with the mount and punch the bolt out along with the bushing.

For cutting, I recommend a saws-all with a carbide-tipped blade as the safest option. Be careful to not cut into the mount too much. If you don't have a saws-all, you could try to cowboy it with an angle grinder with cut-off wheel. Check clearance and geometry to make sure the wheel is actually big enough to cut through before the grinder shaft or body hits. If you cut the head, hit it with a flap disc on an angle grinder (most under-rated angle grinder tool IMO) to get it flush with the mount so you can punch it through. Hell, you could flap-disc off the entire head - would probably be safer than using a cutting wheel under there. 40 grit flap discs take material off amazingly fast.

Apologies for the long post. I've been where you are and like to help folks who are trying to help themselves!

This will get the rust off the bar and plates in no time. Beats the heck out of hand brushing.

https://www.amazon.com/Gunpla-Brush-Crimped-Tempered-Bristles/dp/B0787R6WJY/ref=mp_s_a_1_2?ie=UTF8&qid=1539046956&sr=8-2&pi=AC_SX236_SY340_FMwebp_QL65&keywords=gunpla+wire+brush+hex&dpPl=1&dpID=51Ca3ps3v2L&ref=plSrch

I'm thinking about buying something like this

or maybe even this

I'd just stipple it. I can tell you what to buy and how to do it including the borders. You'll need the following:

https://www.amazon.com/Dremel-107-Engraving-Cutter-Shank/dp/B00008Z9ZV/ or https://www.amazon.com/Dremel-106-Engraving-Cutter-8-Inch/dp/B00008Z9ZU

https://www.amazon.com/Dremel-120-volt-Variable-Attachment-Accessories/dp/B075174NCV/ (you may have your own dremel, but definitely get a flex shaft for it)

https://www.amazon.com/HTS-401B3-Multi-Grit-Diamond-Medium/dp/B00U0E0KRE

https://www.amazon.com/AUSTOR-Grinding-Polishing-Accessories-Attachment/dp/B078Y5XGM8 (careful with these, light touch and keep it moving)

https://www.amazon.com/Flitz-Multi-Purpose-Fiberglass-Aluminum-Sterling/dp/B000MUSOW4

First use your engraving cutter to cut the borders that you've drawn on with a water-removable Stabilo marking pencil. Try to cut as smoothly as possible, with a steady hand. Don't try to cut it all at once, be patient (be patient for all of this, it took me a whole week doing a little at a time to complete the whole process, and turning my dremel off periodically because I have an older model flex shaft that gets hot after some use - solved this by wrapping the grip with bicycle inner tube)

The smoother you cut it the easier the rest will be. Some people just use the engraving cutter for borders, but I followed someone's guide and then used the diamond burs to smooth it out and polish it. Go from the lowest grit to the highest. You can either use the ball bits that are the same size as your cutter, or use the rounded cylinder bits. You can angle the cylinder bits in certain ways to get around curved surfaces, you'll kind of have to experiment with that. Once you get to the highest grit, I found that the only way to get it near-glass smooth was to apply a lot of pressure. It doesn't remove much material and you kind of want it to heat up the plastic to get it smooth. Then, still not satisfied with this, I got those felt wheels and cut the very tip off the smallest one, and used a bit of flitz paste, and then went over all the borders. That got it close enough for me. You can get more advice from the Weapons Stippling group on Facebook.

After you do the borders, I use the round tip on the walnut hollow wood burner on a medium heat setting. You don't want it too hot, not with the P80 plastic anyway. My technique was to press in, not too much but just enough, and drag downwards. A random totally pattern is best, I did a somewhat orderly snake pattern and then went over it again and smeared it out to give it a more organic texture. Then I went over it one more time, lightly and fastly rubbing all along the surface to blend the ridges that were created into the rest of the texture. You can do this several times to get it just right. The result is a texture that is grippy, yet not rough. That's how I like it, but you can experiment. The key is not to heat it up too much and don't stick any of the tips in too deep, and don't try to do it perfectly ordered unless you've gotten good at that with practice and are using an appropriate tip. You can make your own tips out of #8-32 brass screws or buy blanks from OT Defense, or some other place.

Can’t say that I’ve used this particular brand but this is the style I use for polishing yacht railing. 3m has a similar product and are about $10-12 a pop for their 4-1/2 wheels.

uxcell 4 Inch Nylon Fiber Polishing Wheel Sanding Buffing Disc Abrasive Wheels for Angle Grinders 10 Pcs https://www.amazon.com/dp/B07KC71TYT/ref=cm_sw_r_cp_api_i_PUWZDbM2RYX83

If you can use a da sander to get the tube to at least 180-220 then 320. Then hit it with the polishing wheel. Makes quick work of it. Best of luck.

https://www.amazon.com/PFERD-67347-POLIFAN-CURVE-Zirconia/dp/B07GT6P5T1

Can’t say enough about these wheels. They make things so much easier and last longer.

This is the one I currently have, that I'm looking to replace. I thought of purchasing the same thing, but I want to try these ones because I'm broke and it's a better price-point. 😂

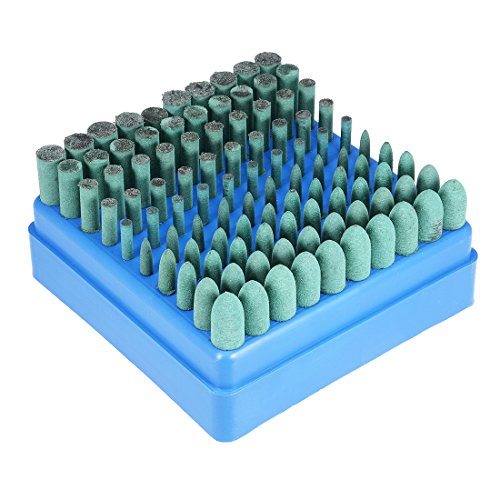

Once it's out of the flask it comes off pretty easy I polish with the 3m rubber publishing wheels like these There is a mild acid that is supposed to be good at breaking this stuff up but I haven't tried it yet https://www.amazon.com/BUYGOO-Abrasive-Bristle-Brushes-Mandrels/dp/B07G8WC2QF/ref=mp_s_a_1_5?keywords=3m+polishing+disc&qid=1573009011&sprefix=3m+polishing+di&sr=8-5

Would this 3K-5K SiC sandpaper work for the CC4 and this 7K to 15K SiC sandpaper work for a Spyderco ceramic or maybe 2?

I use mine on steel all the time. Cut off wheel;http://www.amazon.com/Dremel-409-Cut-off-Wheels-thick/dp/B00004UDGX/ref=sr_1_1?ie=UTF8&qid=1381031263&sr=8-1&keywords=dremel+cut+off+wheel

Used a long marker, and angled it in maybe 20 degrees. Traced everything, then used a utility knife with a fresh blade and cut straight down. Peeled the majority of the material back with my fingers, Kaizen foam has layers you can peel back, but it won't come out in that layer perfectly clean. Test fit everything, cut away more where needed, in small increments because I wanted it super clean looking. Once I got the outline exactly how I wanted it, took a dremel with an abrasive stone head, and pointed it straight down and used it to clean up the lumpy, messy, bottom. Even punching straight down to remove material (especially for the magazine slots this was necessary) it was very effective. Just had to be careful with it, and it worked like a charm! Cleaned up the corners with some careful exacto knife work.

FastCap Long Nosed Pattern Marker https://www.amazon.com/dp/B002NQPEE6/ref=cm_sw_r_cp_apa_i_5k.1Db4YZ6WX8

(I didn't use this set, just using this link to show what I mean by abrasive stone head, I used a cylinder for the flat top, to flatten)

Oudtinx 100 pcs Abrasive Stone Points Electric Grinding Dremel Accessories Polishing Grinding Head Wheel Tool Kit For Dremel Rotary Tool (Red) https://www.amazon.com/dp/B07FN7G7JK/ref=cm_sw_r_cp_apa_i_Vn.1DbBJJHE0A

I had the opportunity to use a tumbler at my (then) place of work. The metal workshop at the prototyping department had a Rösler TE-15 R 360/870 Tub vibrator not in use at the time. We ended up using tumbling media that was in stock, which were Rösler RM 04/10 S (4mmx10mm angle cut triangle ceramic media) and Rösler RM 02/02 D (2mmx2mm Triangle ceramic media). We used Rösler FC 124 S liquid compound (originally intended for tumbling metal parts) mixed with water in a continuous trickle flow, just enough to keep the parts and and media moist without submerging. The tumbler was fitted with a divider, allowing use of both media at the same time in separated compartments.

All of these were acquired directly from RÖSLER BENELUX, I don't know if these can be acquired easily by a regular consumer.

Rösler information PDF about process media: https://de.rosler.com/fileadmin/Files/Prospekte/Gleitschlifftechnik/DE_EN_Consumables_GB_130.pdf

Rösler information PDF about the tub vibrator (tumbler): https://de.rosler.com/fileadmin/Files/Prospekte/Gleitschlifftechnik/DE_EN_Tub_vibrators_GB_129.pdf

The water and compound significantly improved the grinding effectiveness, as well as eliminating airborne grinding dust, which was present in the comparative dry test run we did. I would advise perhaps looking into a method of water sealing you tumbler or replacing the bowl with a (bottom) sealed metal version. The compound's effect might be approximated by adding a little dish soap to the water used to improve dust removal, as non of the metal-specific properties are needed for this application.The tumbling media you linked has a shape comparable with what I used, but appears to be more "grinding". This might help reduce total tumbling time with your less powerful tumbler, though it might also adversely effect the finer part details. To better preserve detail, these smaller media from the same supplier might be more suited: 4x4mm or even 2x2mm.

I will look if i can find any of the tumbled parts and add a photo for reference later.

Sure! I am no expert, but I like my results. Here is what I did.

The whole evolution took less than 20 minutes.

Is this what you’re talking about? https://www.amazon.com/GOXAWEE-Abrasive-Refinishing-Polishing-mandrels/dp/B075SV63VC

Like this, you mean? https://www.amazon.com/uxcell-Diamond-Grinding-Sanding-Polishing/dp/B071SD8LTP/ref=pd_bxgy_3/138-6533951-9210162?_encoding=UTF8&pd_rd_i=B071SD8LTP&pd_rd_r=1b7c5c59-5aeb-11e9-b29f-6f56b9d52ae1&pd_rd_w=xkQTZ&pd_rd_wg=bH7NV&pf_rd_p=a2006322-0bc0-4db9-a08e-d168c18ce6f0&pf_rd_r=XSRD1H4256C7AASSDCMV&psc=1&refRID=XSRD1H4256C7AASSDCMV Can it be cut down to a smaller size? 6in diameter is a bit unwieldy.

https://www.amazon.com/Dremel-409-Cut-off-Wheels-thick/dp/B00004UDGX/ref=sr_1_16?ie=UTF8&qid=1522925292&sr=8-16&keywords=dremel+accessories

An angle grinder and concrete grinding disc would lower the time substantially.