(Part 3) Best soldering stations according to redditors

We found 1,174 Reddit comments discussing the best soldering stations. We ranked the 170 resulting products by number of redditors who mentioned them. Here are the products ranked 41-60. You can also go back to the previous section.

I highly recommend the

Hakko 936 soldering ironHakko 888 soldering iron, which is still actually available. It's hard to fathom how a $100 soldering iron could be that much better than a $20 one, but once you start doing anything more serious than just sticking some wires together, it's worth it.As for other tools,

As for components, I've been buying them piece-meal for years, so other's will probably be able to yield you a better recommendation for kits than anything I can find just from a quick search. I do mostly digital work, so as far as passives, my main stock is:

If I need any other resistor for a specific project, I'll tend to just buy an extra 10 and keep them in labeled coin envelopes.

Random other pieces:

Edit: Fixed the soldering iron model.

Disclaimer: I'm using my Amazon Associate links for all of these, which always feel a little amoral and a conflict of interest, but really, if my apartment were to go up in flames and I could afford it, I'd buy every link on this list right now. Does anyone have strong opinions one way or the other on using them?

Im in ireland so no its not grounded...

The air isnt dry enough here to even be bothered with any antistatic precautions

Years of working with computers and components and i have never zapped a part...

As for the blue mats

Got the one on the left and the middle one on amazon.co.uk for pretty cheap... they have places to put screws and stuff and theyre thick and dont slide around in the desk

(Middle one is SUPER shitty... dont get one like it)

Anti-Static Soldering Mat,... https://www.amazon.co.uk/dp/B075D9R8PZ?ref=ppx_pop_mob_ap_share

The one on the right is brand new and i got it from a supplier of mine but its the exact same as the amazon one just €4 cheaper

I like it! Here is the iron I used: http://www.amazon.com/Soldering-Station-Features-Continuously-Variable/dp/B00IOVN0SQ/ref=cm_cr_pr_pb_t

You can buy some switches pre-made, but unfortunately you're pretty much limited to blue LEDs... And without modifying the driver, the flashlight's behavior will become erratic, especially with a backwards-mode driver like the A6. The parts are pretty cheap though! So if you're willing to learn, buy extra and practice until you get it right!

These are cheap and a good way to get some practice in without fear of messing up your flashlight parts!

What he's politely saying is that your soldering iron sucks ass.

If you can't spring for a TS100 buy a cheapo noname $50 station that is not on batteries. You can already work with something like this

I would honestly buy them separately. A helping hands like this one, and a lamp like this.

Using something like:

http://www.amazon.com/Aoyue-968-Digital-Rework-Station/dp/B000HDG0AO

and

http://www.amazon.com/Aoyue-INT863-Infrared-Preheating-Station/dp/B008GG74CW/ref=sr_1_3?s=hi&ie=UTF8&qid=1347486267&sr=1-3&keywords=smd+preheater

You then basically need to heat the PCB up with the pre-heater 90% of the way, then use the top heater for the last 10%. The goal is to melt down the lead free solder balls to where they are liquid. Using liquid flux helps tremendously in reconnecting the BGA grid.

When people throw cards into the oven, even at 200F for 12 hours, they don't think about the electrolyte capacitors that will burst and release toxic chemicals into their oven.

I normally don't preach on reddit, but if you don't know what you're doing, don't bake your fucking electronics.

Everything looks messy, and most don't look solder properly. I say you de-solder everything, clean everything up and start over.

Follow this wiring diagram, that can be found on Seymour Duncan website. That wiring diagram is a standard tele.

If you don't know how to solder there are some good YouTube videos on soldering. A quick video on soldering

Just make sure you have a proper soldering iron that's about 40 watts or higher. It's important not to destroy the internals while soldering and having proper soldering iron will help. The longer you have to hold on the soldering iron to the electronic the greater the chance you may damage it.

This would be a good soldering iron.

Pricey but worth it if you plan to do your own work.

Anyways good luck and have fun. I have always found soldering peace and relaxing. If you have the proper tools.

I hate to say it, but RadShack makes my favorite budget desktop soldering iron. I have one of these and it works wonderfully. I've been through about 40 tips over the last 3 years with it, not counting one-use modified tips.

At the school lab, we were using this (in quantity at lab desk) or this (instructor's, who would loan it if we knew how to solder). I am going to miss the school lab. Transferring to the next higher level at a different university, where a friend attends, and their lab sucks.

If I bought a new one, I'd get the Weller WD1002. Until I upgrade to that, I'll keep my radshack 64-053.

If you buy a $13 soldering iron, you're buying a $13 soldering iron. Some will work better, some will work worse. Really doesn't matter where you bought it. I never had one last more than a few months.

If yours started out working ok then didn't, make sure your tip is clean. A highly oxidised tip left on overnight isn't going to work well, no matter the iron... if your tip is black, replace it. If it only came with a fine point tip, consider a different shape tip. Fine point tips (generally) only work well with higher power soldering irons.

If you want contactless-soldering, then you're not looking for an iron. You're looking for either a hot air reflow station or an iRDA station. Irons are meant to touch the solder to melt it. Hot air works with solder paste, meant for very low temp soldering (SMD safe). iRDA uses infrared light to melt solder, generally used for specialized surface soldering.

***

It sounds like you may be a little new to soldering, so I also highly recommend this comic to you... Soldering is Easy - PDF. I highly recommend it to those who have been around the block a few times as well.

Cheapest I could find on Amazon is a ZENY knock-off: https://www.amazon.com/F2C-853d-Supply-Soldering-Station/dp/B018LFTWTK

The real thing is $108 from Yihua: https://www.amazon.com/YIHUA-Supply-Soldering-Station-Welding/dp/B01IBQ8X8U/

>These are cheap and a good way to get some practice in without fear of messing up your flashlight parts!

Yes, they are cheap but not at that price. Wow! Those go for less then $2 on aliexpress.

I do, wholeheartedly, encourage the use of cheap kits/suites for practicing soldering.

Buy this one and you'll never have to buy another. It's not cheap, but it's quite reasonably priced for what you get.

This

https://www.amazon.co.uk/Anti-Static-Soldering-Preciva-Heat-resistant-Multi-purpose/dp/B075D9R8PZ/ref=sr_1_3?ie=UTF8&qid=1550920588&sr=8-3&keywords=soldering+mat

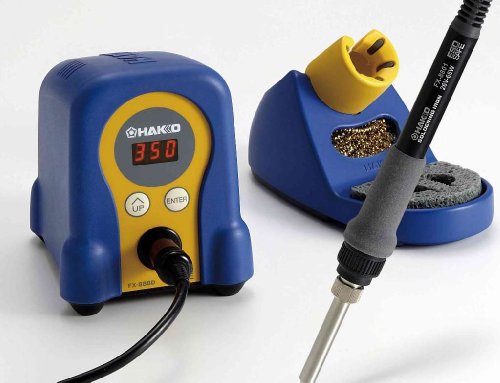

Second on this... The hakko is my preferred:

​

https://www.amazon.com/dp/B00ANZRT4M/ref=sxts_kp_tr_2?pf_rd_m=ATVPDKIKX0DER&pf_rd_p=8778bc68-27e7-403f-8460-de48b6e788fb&pd_rd_wg=dJcvU&pf_rd_r=EPE070JN83NRPFGGF30K&pf_rd_s=desktop-sx-top-slot&pf_rd_t=301&pd_rd_i=B00ANZRT4M&pd_rd_w=CwLRG&pf_rd_i=soldering+station&pd_rd_r=df9f066c-f01a-4011-a950-5df10fee98d3&ie=UTF8&qid=1542646064&sr=2

​

But on a "dime", I'm pretty happy with my weller:

https://www.amazon.com/Weller-WLC200-Stained-Soldering-Station/dp/B0006PYP82/ref=sr_1_7?s=industrial&ie=UTF8&qid=1542646098&sr=1-7&keywords=weller+soldering+station

​

I wouldn't go any below that. I still regret my 10 pack of weller 40 watts I bought for my students.

Thanks for the suggestion.

The Quick 861DW looks like a sexy little unit. Unfortunately at $428 Canadian pesos, it's a bit outside the price range I wanted to spend.

Trying to keep my expenditure around $100-200 for this (will update the question to mention this).

This is a pretty awesome iron

https://www.amazon.com/X-Tronic-Model-3020-XTS-ST-Soldering-Station-Complete/dp/B079VVHPPS/ref=mp_s_a_1_1_sspa?keywords=xtronic+soldering+station&qid=1572960802&sprefix=xtronic&sr=8-1-spons&psc=1&spLa=ZW5jcnlwdGVkUXVhbGlmaWVyPUE1SDY4UVpHMkNEOEomZW5jcnlwdGVkSWQ9QTAzNjMxNDRKQVlBOUE0WkRYMUcmZW5jcnlwdGVkQWRJZD1BMDYzMTgyNDFRNEdPRUZIV0g3NVgmd2lkZ2V0TmFtZT1zcF9waG9uZV9zZWFyY2hfYXRmJmFjdGlvbj1jbGlja1JlZGlyZWN0JmRvTm90TG9nQ2xpY2s9dHJ1ZQ==

And add the solder https://www.amazon.com/gp/aw/d/B00030AP48/ref=ppx_yo_mob_b_inactive_ship_o1_img?ie=UTF8&psc=1

Never burned solder with these two. Never over heated or melted anything that wasn’t supposed to be heated up.

Ec3 connectors

https://www.amazon.com/gp/aw/d/B00XC7QKF2?psc=1&ref=ppx_pop_mob_b_asin_title

Quick 861dw https://www.amazon.com/Quick-861DW-Digital-Station-Display/dp/B00EID23J6

Louis Rossman did a YT review on it. It's a great machine and not too expensive. I bought one and love it.

for surface mount, you need a hot air rework station, and most likely an AmScope or similar.

I would suggest watching a few of Louis Rossmann's videos to get an idea of what would be involved.

Hot air station, Preheater, Dual thermometer.

Well, an adjustable soldering station is the minimum, and there are a few $20 soldering stations that are OK for occasional use; For $80-$100 you'll get something that'll last a lot longer :-)

http://www.amazon.com/Electronix-Express-0603DZ99-Soldering-Continuously/dp/B00IOVN0SQ/ref=sr_1_17?ie=UTF8&qid=1463187980&sr=8-17&keywords=soldering+station / http://www.amazon.com/MPJA-Mini-Solder-Station-ZD-99/dp/B008B86XOK/ref=sr_1_2?ie=UTF8&qid=1463188072&sr=8-2&keywords=soldering+station+mini

http://www.amazon.com/gp/product/B00AWUFVY8?keywords=hakko%20fx-888&qid=1444332307&ref_=sr_1_2&s=industrial&sr=1-2

You can even get soldering irons for under $2 at Aliexpress. Enough to occasionally solder two wires together; But especially the cheaper soldering irons have horribly build-quality and tips that don't last long. :-)

Also, i recently bought a small tip no-name one for school use, http://www.amazon.com/Soldering-Station-Solder-Adjustable-Heating/dp/B017VYC9GU/ref=sr_1_3?ie=UTF8&qid=1463188072&sr=8-3&keywords=soldering+station+mini (I don't know if this one is actually identical), which works surprisingly well (at least better than the $20 ones).

For your child: http://mightyohm.com/blog/2011/04/soldering-is-easy-comic-book/

.

Electronics: Really do get "getting started in electronics", such a good introduction, the comic-y drawings make it easy to understand how and why electronics work.

this is what I have - the 968 from the same company. It uses the same air pump to run a simple smoke filer for the iron, and thus keeps my room from smelling odd.

Indeed. This and this are perfectly adequate for an enormous amount of practice, and come to less than $40, delivered.

It's way, way better kit than what was available inexpensively when I got started.

Hi Eric,

Congrats! It's always fun to unlock new skills and easier SMD soldering is definitely one of them.

I just got done doing my first batch run of one of my boards and I found a heat gun station really made it easy. I could also adjust things with tweezers while heating them up. Maybe check out this guy: https://www.amazon.com/gp/product/B000I5JXA0/ref=s9_acsd_hps_bw_c_x_20_w

For the tops of my board, I didn't even bother using my stencil, I just used the syringe like you did, and it turned out great. The hot air rework station is a real life saver.

Also, if you want to get very precise with your solder paste you might want to try out OSH Stencils. I just used their stainless steel stencil for my board and the precision is easy if your board is less than 5"x5" (outside of 5"x5" my paste would smear, but was still solderable). Check 'em out: https://www.oshstencils.com/#

I have this and it has worked well for 3 years. It isn't the best but for $20 you cant beat it.

Electronix Express 0603DZ99 Soldering Station, Features Continuously Variable, Power Between 110-130V, 1.5 mm Pointed Tip https://www.amazon.com/dp/B00IOVN0SQ/ref=cm_sw_r_cp_apa_-LQTzb3J80EFZ

I love this guy, but you can probably find some better deals depending on what you wanna use it for.

I just had this one delivered today to start building my Bottlehead Crack. I have no use on it, so I can’t comment on that, but based on several reviews I read on the old interwebs, it was highly ranked.

X-Tronic Model #3020-XTS-ST - 75 Watt - Soldering Iron Station with 10 Min Sleep Function, Auto Cool Down, C/F Switch, Ergonomic Soldering Iron Plus More (Soldering Station-Complete with 5 Extra Tips) https://www.amazon.com/dp/B079VVHPPS/ref=cm_sw_r_cp_api_i_856VCb3NRNQ38

Through-hole was my choice for precisely that reason. I've done a bit of soldering, but nothing that small. I saw this kit the other day that should be a good soldering practice exercise, maybe after I make that I'll try it with a surface mount.

Sounds like you need a better soldering iron. I purchased http://www.amazon.com/gp/product/B00M1O9ZSG?psc=1&redirect=true&ref_=oh_aui_detailpage_o01_s00 when I first started and have not looked back. It may be cheap but I have had no issues out of it. It has adjustable temp and comes with extra tips which should cover you for anything you will solder on a multirotor.

I recommend putting one on your lab wishlist then. They seriously make a huge difference soldering. I've got one of these, which is a chinese knockoff of a popular Hakko station. It does the job well.

Sure thing. Like with most hobbies, it's when you first get into things that is the most expensive. Thankfully, it's not that bad to get started.

First off, you'll need some solder. That's a meltable metal used to join two things together. This roll will last you for several projects: https://www.amazon.com/gp/product/B000G36BYU/ref=oh_aui_search_detailpage?ie=UTF8&psc=1

Next, you'll need a soldering iron. I've been pretty happy with this one: https://www.amazon.com/gp/product/B00KS8XA2Y/ref=oh_aui_search_detailpage?ie=UTF8&psc=1 but people swear by Weller. I'm not sure I'd get that 40 watt one that's a similar price on Amazon though, I tend to keep mine at a fairly high power and it works nicely that way.

(I'm assuming you have a Harbor Freight near you for the other stuff. They're pretty common) Then you'll want a multimeter. This is your cheapest option, and if you check your junk mail you might have a coupon for a free one: https://www.harborfreight.com/7-function-digital-multimeter-90899.html but it's lacking in audible continuity (translation: if you want to check that two points are electrically connected, it beeps if they are). This might be worth the extra money: https://www.harborfreight.com/11-function-digital-multimeter-with-audible-continuity-61593.html. Or if you really have some money burning a hole in your pocket, get one of these: https://www.harborfreight.com/5-in-1-digital-multimeter-98674.html - that has some extra features that really come in handy, but aren't totally necessary either.

That covers the most expensive tools, but there are still a few odds and ends you'll want.

Do you mean something like this pencil solderer and this solder?

I've never done any soldering before so I'm not quite sure what I need to do. Would watching guides on youtube be enough for a simple soldering job like this?

Here's a super cheap solder pencil: Link

and some solder

Good quality adjustable irons can be quite a bit more expensive, but this should work for a simple cable swap.

This guy is pretty well recommended. I just bought one and it's pretty friggen sweet.

Soldering irons with adjustable heat are usually pretty good. I bought this one and its great. I also use Kester solder 60/40, and have never had problems.

Regarding the Oscope, the best budget option is the DSO nano. It has large enough bandwidth to be good for audio. If you want something more robust with a better reputation and built in multimeter, the TPI 440 is an excellent option. Its available for $250 shipped from www.kiesub.com .

Yeah, some people on Amazon complain about the actual iron falling apart, but I've had 2 for over a year that get daily use, and have had no problems.

We do PC board/Laptop DC Jack repair and SMD rework with the 968

Knock-off Hakko 936 tips from ebay work OK, and cost ~$0.75 US each delivered.

If your hands are shaking and you're worried it'd make it too hard, you can always get one of these miniature holders to keep the mini pretty still, then if you grasp your hand with your other hand to stabilize it, it should make painting much, much easier.

https://www.amazon.com/dp/B079VVHPPS/ref=cm_sw_r_cp_api_i_u81-Ab0BZ4Z1Q

And he is looking at this:

https://www.amazon.com/dp/B00ANZRT4M/ref=cm_sw_r_cp_api_i_n91-AbMVGHT1R

Looking for a soldering iron, between these two, any suggestions? (or other irons <= that price)

&#x200B;

https://www.amazon.com/dp/B01DGZFSNE/ref=psdc_13837391_t2_B000AS28UC

&#x200B;

https://www.amazon.com/Weller-WLC100-80-Watt-Soldering-Station/dp/B0006PYP82/ref=sr_1_3?crid=32YA0P77ZHRAC&keywords=weller%2Bsoldering%2Biron&qid=1562086372&s=gateway&sprefix=weller%2Bsoldering%2B%2Caps%2C176&sr=8-3&th=1

If you want high quality stuff, you should check out hakko. They make really high quality machines.

If you want something cheaper, you can check out these ones: https://www.amazon.com/dp/B018LFTWTK/ref=sspa_dk_detail_2?psc=1&amp;pd_rd_i=B018LFTWTK&amp;pd_rd_w=MLkUQ&amp;pf_rd_p=8a8f3917-7900-4ce8-ad90-adf0d53c0985&amp;pd_rd_wg=f1owt&amp;pf_rd_r=M05VEJJHGT4VANVB9SA0&amp;pd_rd_r=37f01a82-a8e5-11e9-8fbb-f12e78b4f007

I've bought a couple of these; they're pretty good for what they cost.

This may sound a bit dumb but couple quick tips on soldering connectors.

For smaller wires, I use a hakko solder station with a narrow tip and can fine tune the heat. Remember to clean your tips and replace them as needed! They are a wear item and can really impact your joints.

Definitely need to invest in a good soldering iron if you want to get into building. Ideally something like this one.

https://www.amazon.com/F2C-853d-Supply-Soldering-Station/dp/B018LFTWTK

this thing? it has a power supply in it?! well shiiittttt buying it now...

oh and welcome to Canada

https://www.amazon.ca/VIVOHOME-Soldering-Rework-Station-Supply/dp/B07J5W2TVX/ref=sr_1_2?keywords=hot+air+station+power+supply&amp;qid=1565643011&amp;s=gateway&amp;sr=8-2

jesus, gunna have to look around. i'll probably end up with something like this though

https://www.amazon.ca/BK-858A-Brushless-Rework-Station-Stand/dp/B07B8VTWBD?ref_=bl_dp_s_web_16707359011

anyway, game gear can be done without a hot air gun... hmm. i do have shaky hands, maybe i'll do it in the morning prior to my coffee. i've got a week off of work coming up, i think i'll buy replacement caps now and see how it goes. as for the method to remove the old caps you mention, i've seen youtubers do it that way, i think 8-bit guy was the guy doing it. made it look pretty easy. im mostly worried about the "caps that look like SMD resistors" i do not know their names.

Depending on how much you are willing to spend, these are two good options, one cheaper and the other more expensive:

I have the WLC100 and it works great. Remember to test the different settings - 5 gets too hot. I think used mine either on 3 or 4. I start with 5, so it gets hot fast and then switch it to either a 3 or a 4.

Based on the recommendation by Rossman; My package had 3 straight nossles attachments to concentrate the air (which i wish would have been 45° ones) but i'm still very happy. The hose could be a little longer; depends on your setup. Heats quick, when docked it cools down (to prevent burning the table).

Quick 861DW 1000W Digital Rework Station with LCD Display

*english

Hum. Well, we've been trucking along for a while and found some good tricks for keeping it manageable without the solder mask.

We don't have an oven, but we do have a reflow soldering station. If you don't have one available, you may want to look into getting an air bath and reflow station, with a good soldering pencil for touchups. Works great if you are low-volume.

The air bath keeps things pre-heated to the melting point of the solder, so you don't have to tin the pad first. You can then use the solder paste, place the part, and hit it with the reflow gun to melt it in place. Then use tweezers and the soldering pencil to fix up.

Not sure if that is helpful -- if you have a solder oven, you probably have a higher budget than we do. However, this is a pretty good solution for everything but BGA chips.

Though... we also have a trick for BGA, too. Ends up you can double-fold packaging tape, use a laser cutter to poke holes in it in the same pattern as the ball grid, and smear solder paste through the holes. Then manually place the IC, hit it with the heat gun, and you're good.

Our lab is full of hack.

TXINLEI 8586 110V Solder Station, 2 in 1 Digital Display SMD Hot Air Rework Station and Soldering Iron, 12pcs Different Soldering Tips,Solder Wire,Tweezers,Desoldering Pump,700W 480℃ https://www.amazon.com/dp/B07FJ6PNHF/ref=cm_sw_r_cp_api_i_IfYqDb03ZY8XT

I bought this mostly for the hot air station because I have a T12 style soldering station that I like better, but if I’m feeling lazy and don’t want to plug up both stations, I will use the iron from this kit and it works really well. It also comes with various solder tips, tweezers, picks, soldering handle holder, desoldering pump, some cheap solder (I haven’t tested the quality of this solder) and it comes with spare heating elements just in case one burns out.

I like using the K style tips (the one that’s angled). The T12 station I have has the KU tip it’s much smaller and easier to access smaller components. Watch some YouTube videos and get an idea. Don’t get to nervous about messing things up, go down to the thrift shop get an old DVD player or something cheap and practice your soldering and desoldering skills on that. This community is very great for helping others troubleshoot problems.

Also, with capacitors remember to trim legs and make sure you get the negative and positive leads correct, and voltage rating can be equal to or higher than the one being replaced, but capacitance has to be equal.

This one on Amazon seems to have pretty good reviews. I'd recommend getting a stand like this to go with it for safety reasons. (I decided to solder without mine a few weeks ago, and wouldn't you know it, the one time I decide I don't need the stand, I burn myself!)

You can easily spend a lot more on irons, and if you start doing a lot more soldering you may want to make a bigger investment. A lot of people really like the Hakko FX888D, but I personally prefer the Weller WTCPT-60 because I don't like fussing with knobs. (Despite not having a knob, the Weller actually does have very precise temperature control, but depending on what temperature you want you have to buy different tips, which isn't worth the hassle for most people. I use only one kind of solder so it doesn't matter for me, but I digress.)

I've never found any tutorials I really like, and my advice is to just get busy! You'll make a lot of mistakes and do a lot of projects slowly before you get good, and I don't think there's a tutorial out there that will let you skip that. To help you stay pointed in the right direction, here are a few things I look for in a good solder joint:

There are a few intuition issues you should be aware of that I've observed while teaching students to solder. For instance, most of the stuff you'll be soldering is so small that it will be "cold" (as in "too cold to melt solder") the instant you pull the iron away, and cool enough to touch within seconds. Try it if you don't believe me. The part will only stay hot as long as the iron is touching it. You'd be surprised how many people can't get their head around this.

Also, oxygen is your enemy. The longer the part is hot, the more oxidized the surface will become and the harder it will be for solder to stick. This is true even when the joint is hot, but not hot enough to melt solder! So once the iron contacts the work, you have to be expedient. Most joints can be finished in 5 seconds or less, and if you're holding the iron on there for 10 seconds or more but the solder still isn't melting, stop and reexamine what you're doing. You may want to get some fine-grit sandpaper to clean the conductors off before you start again.

Keeping oxygen out of your solder joint is the job of flux, and like /u/avialex (edit: fixed) said it's very helpful (provided everything is relatively clean to begin with). But again it's a balancing act. If you use too much flux you'll make a mess, and raw flux is slightly corrosive and can be very difficult to clean off your work.

There are lots of other tricks you'll learn through practice too. I guess that's where tutorials might come in handy. You'll probably learn to splice wires (probably the most difficult thing to do with a soldering iron) much more quickly from someone with experience on Youtube than struggling through it 20,000 times yourself, doing it a harder way because you didn't know any better.

At the same time though, there's no substitute for practice. This went on a lot longer than I intended, but I think now you have plenty of information to keep in mind as you get started. Good luck and happy soldering!

I typed up a great list last night, then somehow, I managed to screw it up and lost the whole thing. So I decided to heck with it... and found a beer.

Let's try again.

Standard tools:

Standard tools with more specific uses:

Finally, pinball specific tools:

That should be about it. At least to get started. Depending on where you go from there, there are a bazillion things you could spend money on. But since you only have one machine right now, this basic list should take you a very long way. And don't kill yourself buying a ton of expensive specialty tools like fancy soldering irons if you don't think this is something you'll want to do a lot of. If you decide you like it and want to spend more money later, those are great upgrades.

Yeah, avoid anything that says gun. Soldering guns often don't have isolated tips and are too big for hobby soldering unless you really need the power for huge wires and chasis mount stuff like Nico said. Even if you are working with heavier stuff you can pre-heat with a hotair tool and finish the soldering up with the iron.

Here's a link for reference on the kind of rework station Nico is talking about.

https://www.amazon.com/TXINLEI-8586-Soldering-Different-Desoldering/dp/B07FJ6PNHF/

You can find cheaper one's off AliExpress or ebay but much bellow about 60 dollars and you're going to sacrifice basic quality and saftey. A lot of the super cheap kits don't have ground properly wired inside, if you decide to get one make sure you open the unit up and take a peak inside to ensure that it's grounded properly.

https://www.amazon.com/Hakko-FX888D29BY-ESD-Safe-Digital-Soldering/dp/B00OSM27T8/ref=asc_df_B00OSM27T8

I think that anything less than that price is likely to be a counterfeit.

Heres a similar one https://www.amazon.com/Helping-Soldering-Workshop-Non-slip-Weighted/dp/B07MDKXNPC/ref=mp_s_a_1_4?keywords=helping+hands&amp;qid=1559120440&amp;s=gateway&amp;sr=8-4

I bought this one:

Preciva Silikonmatte 500℃ Hitzebeständige Magnetische Arbeitsmatte Arbeitsunterlage Reparatur Matte Soldering Mat Antistatisch für Lötpistolen, Heißpistolen - 45x 30cm https://www.amazon.de/dp/B075D9R8PZ/ref=cm_sw_r_cp_apa_i_gLp5CbM5HYAN5

This?

https://www.amazon.com/Ram-Pro-Helping-Hands-Magnifier-Alligator/dp/B078SY5DPZ/ref=mp_s_a_1_5?ie=UTF8&amp;qid=1538689327&amp;sr=8-5π=AC_SX236_SY340_FMwebp_QL65&amp;keywords=alligator+clips+stand&amp;dpPl=1&amp;dpID=41ccrKvYGlL&amp;ref=plSrch

Lol. It’s this one I think. My wife gave it to me for Christmas along with a ton of paint.

clamp

It looks like Hakko is a little beyond my budget. I’m considering this Vastar unit

I have the hot air only version of the first one, the 858D. It's okay, gets the job done. I got it on the recommendation of a friend who uses it all the time and is really happy with it.

For a soldering iron though, IMO you'd be better served by something name brand like the Hakko FX888D or the Weller WES51. I have the WESD51 and it has served me well. For J Random Soldering Iron, the temperature control might not be very good, and it might be tough getting different tips.

A decent budget option might be a hakko 936 knockoff, which should have pretty good availability of replacement tips.

ew :P.

http://www.amazon.com/Weller-WTCPT-Temperature-Controlled-Soldering/dp/B00004W463/ref=sr_1_3?ie=UTF8&amp;qid=1398010594&amp;sr=8-3&amp;keywords=weller+60w

my baby, the replacement / specialized tips are so expensive hahah.